Rapid Delivery for High Efficient Pet Food Production Line - Meat Patty Production Line – Ainister

Rapid Delivery for High Efficient Pet Food Production Line - Meat Patty Production Line – Ainister Detail:

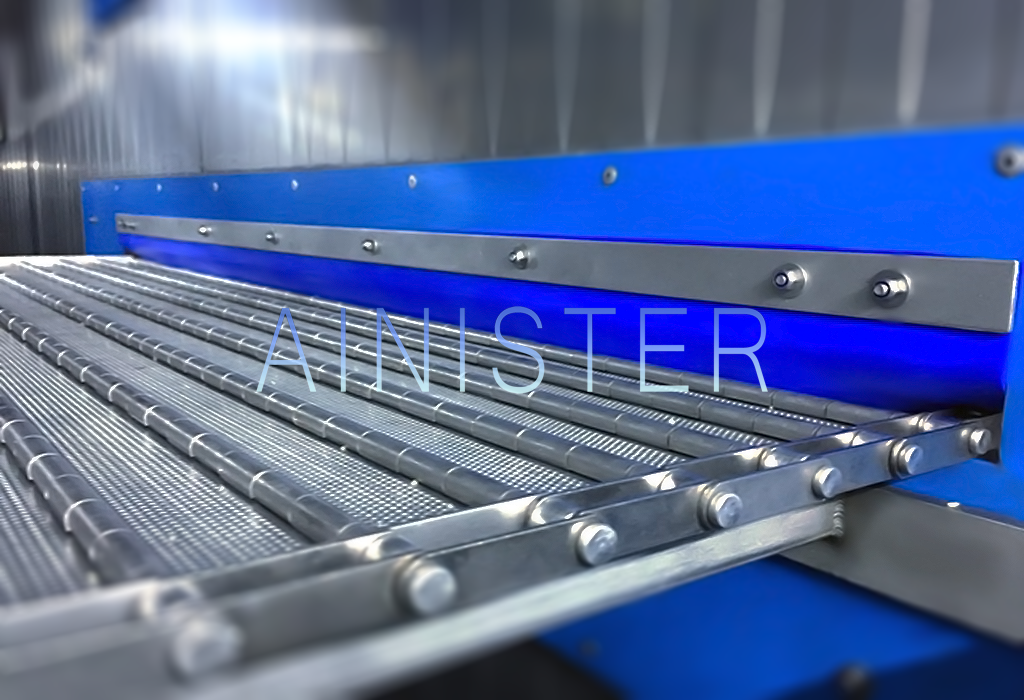

The whole machine is made of stainless steel and other food materials, which meets hygienic standards and HACCP standards, which is easy to clean; the whole machine is designed with safe electrical appliances. Wide range of uses, and a wide range of applicable raw materials, and abundant products. In addition, it is equipped with a sizing machine and a breading machine to become a hamburger patty, chicken chop, and fish patty production line.

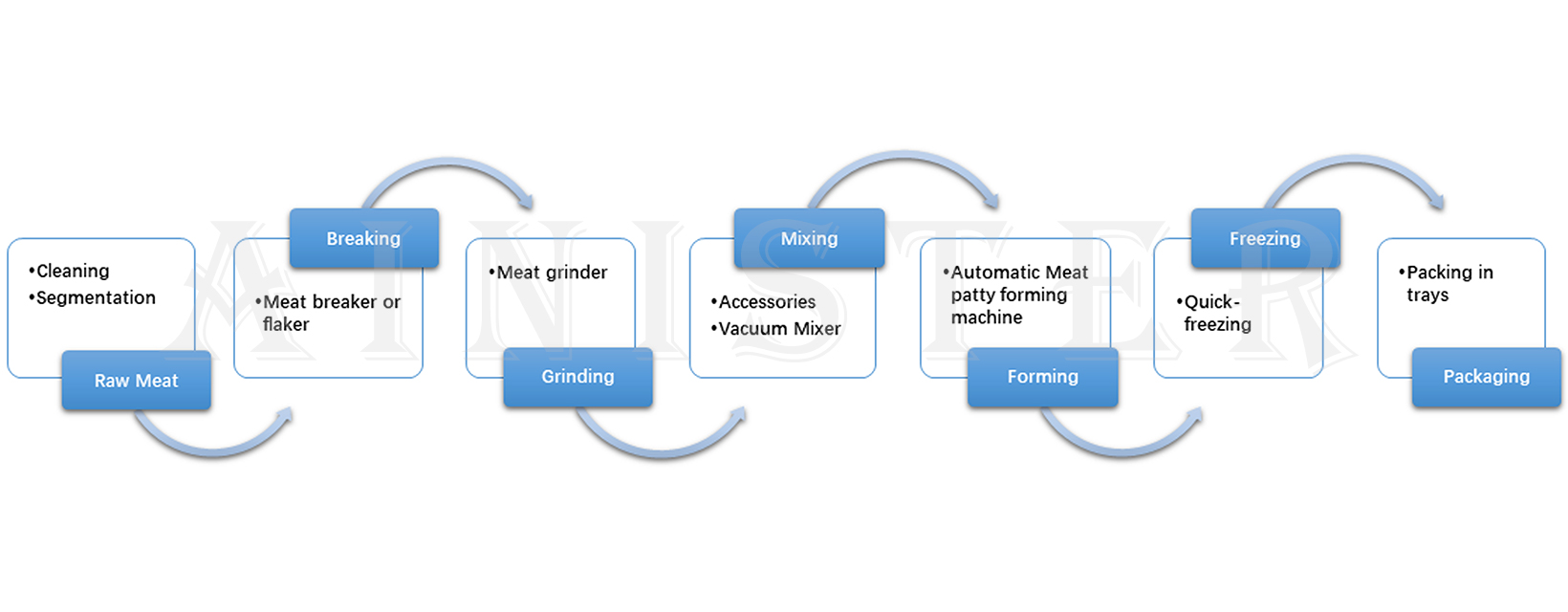

In the process of raw meat processing, the meat grinder can prevent the material from heating up too fast and maintain the freshness of the material, and then add auxiliary materials to meet the production requirements. It can process fresh meat at the same time or directly mince frozen meat at -18 ℃.

The core equipment of meat patty processing-patty forming machine. In order to meet the needs of different outputs, we provide different types of meatloaf forming machines, from single-row to multi-row forming, with multi-functional conveyors, which can realize automated production. It is suitable for customers with different needs from family workshops to large factories.The automatic forming machine can automatically complete the meat filling, forming, output and other processes, and can be connected with a sizing machine, a flouring machine, a frying machine, a cooking machine, a quick-freezing machine, and a packaging machine to a fully automatic production line of mature food.

Product replacement is convenient, fast, and quantitatively accurate, effectively controlling production costs. There are a variety of molds to choose from. It is suitable for forming aquatic products such as meat, poultry, fish, shrimp, potatoes, potatoes, or vegetables. It is not only suitable for minced raw materials but also suitable for the molding of various block products. It can produce hamburger cakes, chicken nuggets, chicken fillets, fish steaks, and other products. After the product is cut, it shows a lumpy shape, and the meat has a strong sense of reality, which is easily recognized by consumers and meets market needs.

The production line can be equipped with quick freezing equipment for easy storage. The quick freezing production line can be matched with spiral quick freezing or quick freezing tunnel according to the production environment. At the same time, you can choose different refrigeration methods, compressor refrigeration, or liquid nitrogen refrigeration.

Specification and Technical Parameter

- 1. Compressed Air:0.06 Mpa

- 2. Steam Pressure:0.06-0.08 Mpa

- 3. Power: 3~380V/220V Or Customized according to different voltages.

- 4. Production Capacity:100kg-2000kg per hour.

- 5. Applicable Products: Beef patty,Burger patty,Chicken patty, etc.

- 6. Warranty Period: One year

- 7. Quality Certification: ISO9001, CE, UL

Product detail pictures:

Related Product Guide:

We are ready to share our knowledge of marketing worldwide and recommend you suitable products at most competitive prices. So Profi Tools offer you best value of money and we are ready to develop together with Rapid Delivery for High Efficient Pet Food Production Line - Meat Patty Production Line – Ainister , The product will supply to all over the world, such as: Sudan, Madagascar, Norway, Our company regards "reasonable prices, high quality,efficient production time and good after-sales service" as our tenet. We hope to cooperate with more customers for mutual development and benefits in future. Welcome to contact us.

1.Do you provide goods or equipment, or solutions?

We do not produce final products, but are manufacturers of food processing equipment, and we also integrate and provide complete production lines for food processing plants.

2.What areas do your products and services involve?

As an integrator of the production line program of Helper Group, we not only provide various food processing equipment, such as: vacuum filling machine, chopping machine, automatic punching machine, automatic baking oven, vacuum mixer, vacuum tumbler, frozen meat/ Fresh meat grinder, noodle making machine, dumpling making machine, etc.

We also provide the following factory solutions, such as:

Sausage processing plants,noodle processing plants, dumpling plants, canned food processing plants, pet food processing plants, etc., involve a wide range of different food processing and production fields.

3.Which countries are your equipment exported to?

Our customers are all over the world, including the United States, Canada, Colombia, Germany, France, Turkey, South Korea, Singapore, Vietnam, Malaysia, Saudi Arabia, India, South Africa and more than 40 countries and regions, providing customized solutions for different customers.

4.How do you guarantee the installation and after-sales service of the equipment?

We have an experienced technical team and production workers, who can provide remote guidance, on-site installation and other services. The professional after-sales team can communicate remotely at the first time, and even on-site repairs.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!