Popular Design for Wasted Meat Beef Patty Production - Canned Beef Production Line – Ainister

Popular Design for Wasted Meat Beef Patty Production - Canned Beef Production Line – Ainister Detail:

Canned beef is more popular all over the world. As a fast food, it has the characteristics of long shelf life, convenient carrying, and simple cooking. From the early manual production of canned food, it has now developed into a fully automated production line, which has greater advantages in terms of output and cost. We can help customers design different packaging types, different sizes, and different shapes of canned food solutions.

The raw materials generally need to be processed manually to remove fascia, fat, lymphatic tissue, etc., so as not to affect the taste and shape. It is then divided into pieces to prepare for the next marinating process. If you choose frozen beef, it needs to be naturally thawed in advance and then processed further. The quality of meat directly affects the taste of the final product.

In different regions, the processing technology is different, you can choose to pickle or directly process. Pickling generally chooses vacuum tumbler series, which can make the raw meat fully absorb the seasoning soup at -0.08mpa, and continuously beat. The tumbler can realize timing operation and stop. With frequency converter speed regulation, the application scene is wider.

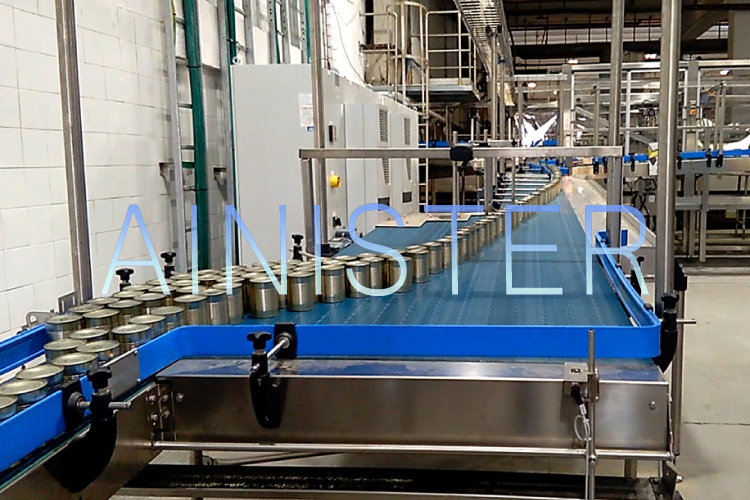

Depending on the output and the type of cans, in addition to manual canning, the production of automated equipment is also the development direction. A variety of equipment can be selected for canning beef, such as a multi-head weighing system. Multi-head weigher is mainly suitable for granular or block products, such as meat, fruit, puffed food, quick-frozen food, pet food, etc., with accurate quantitative and rapid filling.

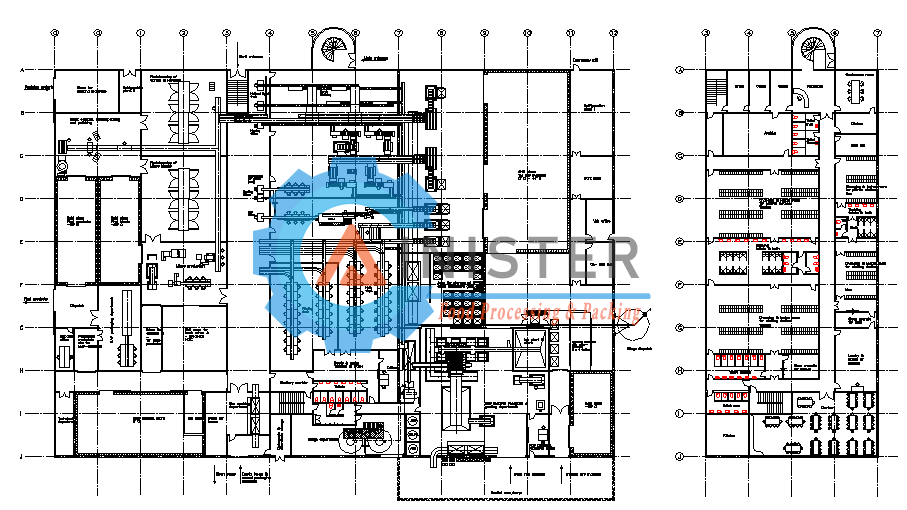

For the cleaning and transportation of the tank, a customized layout is required according to the customer’s plant. Including conveyor track type, width, length, material, etc. If the output demand is great and the production workshop has enough space, you can choose supporting canning equipment to truly realize a fully automated production line. The entire production line is made of food-grade 304 stainless steel, and the overall speed is adjustable. From can cleaning to sealing, final packaging, seamless connection and reasonable space utilization.

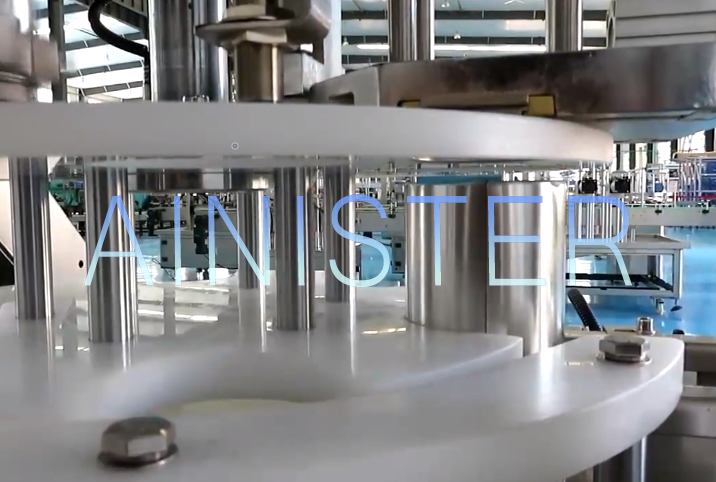

There are many types of canned products, including round cans, square cans, special-shaped cans, etc., which can be matched with different vacuum sealing machines. In order to improve the sealing quality and sealing speed and facilitate the vacuum suction, the sealing machine pre-seals the can and the lid before entering the vacuum chamber for sealing, and then enters the vacuum chamber to perform vacuum suction, first sealing, and second sealing. Road sealed. The sealing speed is adjustable, the size range is wide, and it is perfectly matched with various production lines.

From raw material processing to filling and sterilization, food will be contaminated by microorganisms to varying degrees. The higher the contamination rate, the longer the sterilization time will be at the same temperature. This requires sterilization equipment with stable performance and precise temperature control to implement the established sterilization formula without failure and minimal error to ensure the standard and uniformity of the sterilization effect. The continuous sterilization process is adopted. Under the environment of 120℃, the sterilization work must be completed at one time from the beginning to the end without interruption, and the food cannot be sterilized repeatedly.

Specification and Technical Parameter

1. Equipment type and model:

| No | Name | Model | Quantity |

| 1 | Meat Grinder | JR-D120 | 1 |

| 2 | Vacuum Tumbler | GR-2500 | 1 |

| 3 | Can Conveyor | HC-A | 1 |

| 4 | Filler Machine | GT-2000 | 1 |

| 5 | Can Washing Machine | GT-D10 | 1 |

| 6 | Vacuum Sealing Machine | GT-100 | 1 |

| 7 | Sterilization Kettle | HS-1500 | 1 |

2. Compressed Air:0.06 Mpa

3. Steam Pressure:0.06-0.08 Mpa

4. Total Power:34kw 3~380V/220V Or Customized according to different voltages.

5. Production Capacity:1000kg-2000kg per hour.

6. Applicable Products: Luncheon meat, canned beef, canned pork, canned meat, etc.

7. Warranty Period: One year

8. Quality Certification: ISO9001, CE, UL

Product detail pictures:

Related Product Guide:

We've one of the most advanced generation tools, experienced and qualified engineers and workers, recognized good quality manage systems and a friendly skilled product sales workforce pre/after-sales support for Popular Design for Wasted Meat Beef Patty Production - Canned Beef Production Line – Ainister , The product will supply to all over the world, such as: Uzbekistan, Thailand, Poland, We follow superior mechanism to process these products that ensure optimum durability and reliability of the products. We follow latest effective washing and straightening processes that allow us to offer unmatched quality of products for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

1.Do you provide goods or equipment, or solutions?

We do not produce final products, but are manufacturers of food processing equipment, and we also integrate and provide complete production lines for food processing plants.

2.What areas do your products and services involve?

As an integrator of the production line program of Helper Group, we not only provide various food processing equipment, such as: vacuum filling machine, chopping machine, automatic punching machine, automatic baking oven, vacuum mixer, vacuum tumbler, frozen meat/ Fresh meat grinder, noodle making machine, dumpling making machine, etc.

We also provide the following factory solutions, such as:

Sausage processing plants,noodle processing plants, dumpling plants, canned food processing plants, pet food processing plants, etc., involve a wide range of different food processing and production fields.

3.Which countries are your equipment exported to?

Our customers are all over the world, including the United States, Canada, Colombia, Germany, France, Turkey, South Korea, Singapore, Vietnam, Malaysia, Saudi Arabia, India, South Africa and more than 40 countries and regions, providing customized solutions for different customers.

4.How do you guarantee the installation and after-sales service of the equipment?

We have an experienced technical team and production workers, who can provide remote guidance, on-site installation and other services. The professional after-sales team can communicate remotely at the first time, and even on-site repairs.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.