OEM manufacturer Fully Automatic Pasta Production Line - Chinese Sausage Production Line – Ainister

OEM manufacturer Fully Automatic Pasta Production Line - Chinese Sausage Production Line – Ainister Detail:

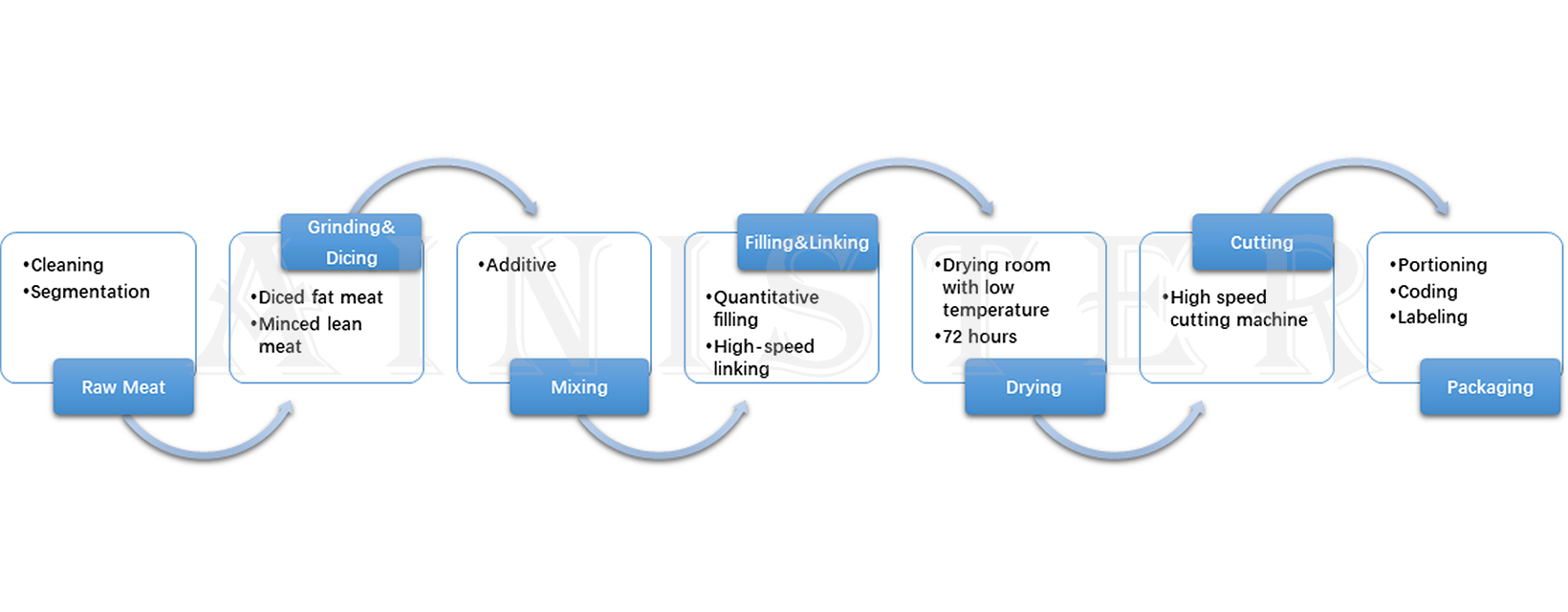

How to make Chinese-style sausage in sausage factory?

Chinese-style sausage refers to meat products with Chinese characteristics that are made from meat as raw materials, cut into cubes, supplemented with auxiliary materials, and poured into animal casings, and then fermented and matured. It is the largest category of meat products in China. , Its craft is somewhat similar to salami. According to different tastes, there can be different products such as sweet and spicy.Based on this, it is also possible to make salami by changing some equipment.

Equipment Display

Chinese-style sausages are generally mixed with lean pork and fatty meat in a certain proportion, and the ratio can be adjusted according to taste requirements. Lean meat can be minced into meat particles with a meat grinder, and fat can be cut into diced meat with a dicing machine. The frozen meat can be processed directly, or fresh meat can be used as the raw material.

The mixing of meat can choose a mixer, which adopts double twisted auger structure, two-way mixing, with frequency converter speed regulation, arc box structure so that there is no dead corner inside, the material is stirred evenly, and it is easy to clean at the same time. In addition, a weighing system is optional, Realize automated production.

Chinese sausages generally use natural casings as filling materials. Including the small intestines of sheep or pigs. Of course, protein casings are also used to make Chinese sausage products. One is the difference in taste, and the other is the difference in the completeness of the final product appearance. But all need to use vacuum filling equipment, because the materials are granular, not minced meat, equipment with a vacuum system is more conducive to the flow of materials, the quantitative will be more accurate.

Sausages are uncooked sausages like salami. The production method used is air-drying. In the traditional case, it takes about 15 days to dry in the natural state. In modern production technology, the drying oven can be used for 72 hours to complete this step. At the same time, it can not be affected by natural environmental factors and maintain a constant temperature. Constant humidity makes the sausage the most perfect state.

After the sausage is cut by the shearing machine, you can choose to place it manually and put it into the packaging machine to complete the final process. For customers with large production requirements and high labor costs, they can also choose a robotic arm for sorting, using a servo system and PLC intelligent control, which is fast and saves labor costs. In addition, the packaging part can choose a variety of packaging forms according to the product market demand, including vacuum packaging, non-vacuum packaging, skin packaging, stretch film packaging, etc.

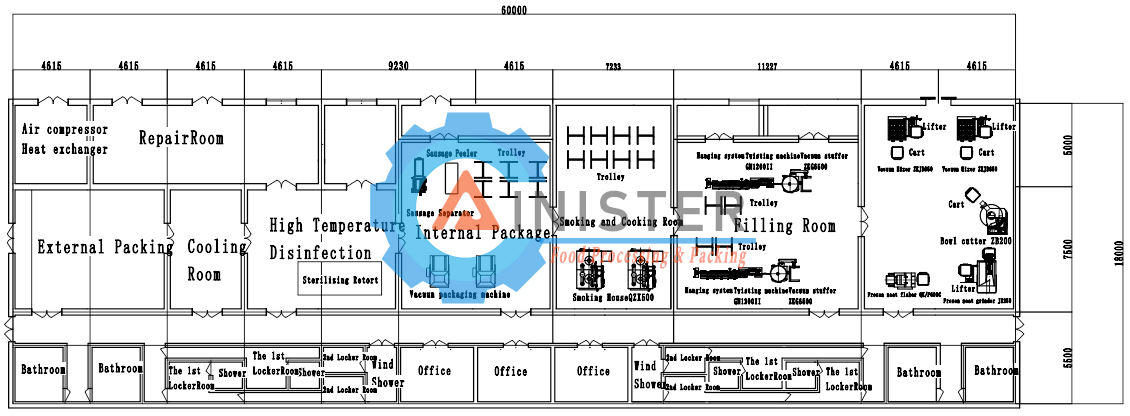

Layout Drawing & Specification

- 1. Compressed Air:0.06 Mpa

- 2. Steam Pressure:0.06-0.08 Mpa

- 3. Power:3~380V/220V Or Customized according to different voltages.

- 4. Production Capacity:200kg-5000kg per hour.

- 5. Applicable Products: Small sausages, twisted sausages, salami,etc.

- 6. Warranty Period: One year

- 7. Quality Certification: ISO9001, CE, UL

Product detail pictures:

Related Product Guide:

Our enterprise since its inception, usually regards product top quality as business life, repeatedly enhance manufacturing technology, make improvements to product excellent and continuously strengthen enterprise total high quality administration, in strict accordance with all the national standard ISO 9001:2000 for OEM manufacturer Fully Automatic Pasta Production Line - Chinese Sausage Production Line – Ainister , The product will supply to all over the world, such as: Gabon, Turin, Russia, All styles appear on our website are for customizing. We meet up to personal requirements with all products of your very own styles. Our concept is to help presenting the confidence of each buyers with the offering of our most sincere service, and the right product.

1.Do you provide goods or equipment, or solutions?

We do not produce final products, but are manufacturers of food processing equipment, and we also integrate and provide complete production lines for food processing plants.

2.What areas do your products and services involve?

As an integrator of the production line program of Helper Group, we not only provide various food processing equipment, such as: vacuum filling machine, chopping machine, automatic punching machine, automatic baking oven, vacuum mixer, vacuum tumbler, frozen meat/ Fresh meat grinder, noodle making machine, dumpling making machine, etc.

We also provide the following factory solutions, such as:

Sausage processing plants,noodle processing plants, dumpling plants, canned food processing plants, pet food processing plants, etc., involve a wide range of different food processing and production fields.

3.Which countries are your equipment exported to?

Our customers are all over the world, including the United States, Canada, Colombia, Germany, France, Turkey, South Korea, Singapore, Vietnam, Malaysia, Saudi Arabia, India, South Africa and more than 40 countries and regions, providing customized solutions for different customers.

4.How do you guarantee the installation and after-sales service of the equipment?

We have an experienced technical team and production workers, who can provide remote guidance, on-site installation and other services. The professional after-sales team can communicate remotely at the first time, and even on-site repairs.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.