Hot Sale for Gyoza Wrapper Making Machine - Luncheon Meat Production Line – Ainister

Hot Sale for Gyoza Wrapper Making Machine - Luncheon Meat Production Line – Ainister Detail:

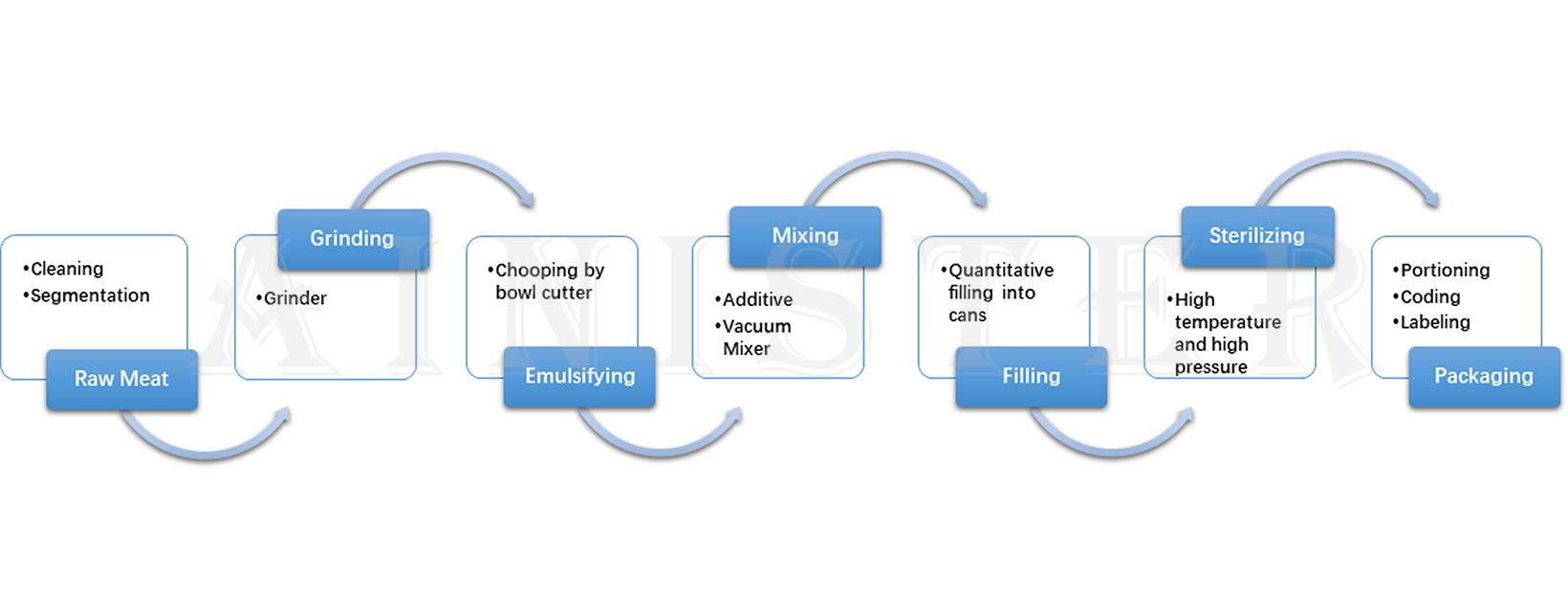

How to make luncheon meat and canned meat ?

Luncheon meat is a common food in daily life. Unlike ordinary canned beef or pork, luncheon meat is more delicate and suitable for more people. The luncheon meat production line uses meat or minced meat as raw materials, which can quantitatively fill raw materials into cans, and has a vacuum-assisted feeding function to avoid pores, defects, product shapes and firmness. This machine can reach 90 times per minute, economical, practical, and low consumption. After work, it is easy to clean and suitable for filling cans of different can shapes and specifications.

Equipment Display

The raw material processing of luncheon meat generally uses the cutting machine, flaker machine, meat grinder, and other equipment. The equipment is made of food-grade 304 stainless steel, equipped with high-strength knives, low wear, and fast speed, and can directly reduce the temperature to about -18 ℃ 25kg standard frozen meat is directly cut into small pieces or slices, and then processed into meat pellets through the meat grinder.The production capacity can satisfy hundreds of kilograms to several tons per hour.

According to different product requirements, some processes may choose fresh meat for processing, and some products may choose to use a tumbler to marinate the raw meat for better taste and even taste, so that the raw materials can fully absorb the seasonings and produce Produce more diverse luncheon meat products. We can work out a more suitable production plan according to the diversified requirements of customers.

The delicate taste of luncheon meat is generally achieved by the high-speed chopping of the bowl cutter machine. At a speed of up to 4500rpm, the meat can be chopped into a minced shape. Equipped with German knives, the temperature rise is small, and it is resistant to abrasion, so that the material can achieve emulsification. At the same time, it can also choose the vacuum function to reduce the product’s bubble content and increase the taste and elasticity.

For meat filling, an automatic stuffer machine with vacuum function is selected, and the conveying system is used to form an automated production line. The size of the can is matched by changing the mold and adjusting the height. The built-in vacuum system helps to fill the material evenly, while the auger system helps the material flow. The conveyor belt can be directly transported to the sealing machine for sealing. No manual transfer is required. Save space and labor consumption.

There are many types of canned products, including round cans, square cans, special-shaped cans, etc., which can be matched with different vacuum sealing machines. In order to improve the sealing quality and sealing speed and facilitate the vacuum suction, the sealing machine pre-seals the can and the lid before entering the vacuum chamber for sealing, and then enters the vacuum chamber to perform vacuum suction, first sealing, and second sealing. Road sealed. The sealing speed is adjustable, the size range is wide, and it is perfectly matched with various production lines.

From raw material processing to filling and sterilization, food will be contaminated by microorganisms to varying degrees. The higher the contamination rate, the longer the sterilization time will be at the same temperature. This requires sterilization equipment with stable performance and precise temperature control to implement the established sterilization formula without failure and minimal error to ensure the standard and uniformity of the sterilization effect. The continuous sterilization process is adopted. Under the environment of 120℃, the sterilization work must be completed at one time from the beginning to the end without interruption, and the food cannot be sterilized repeatedly.

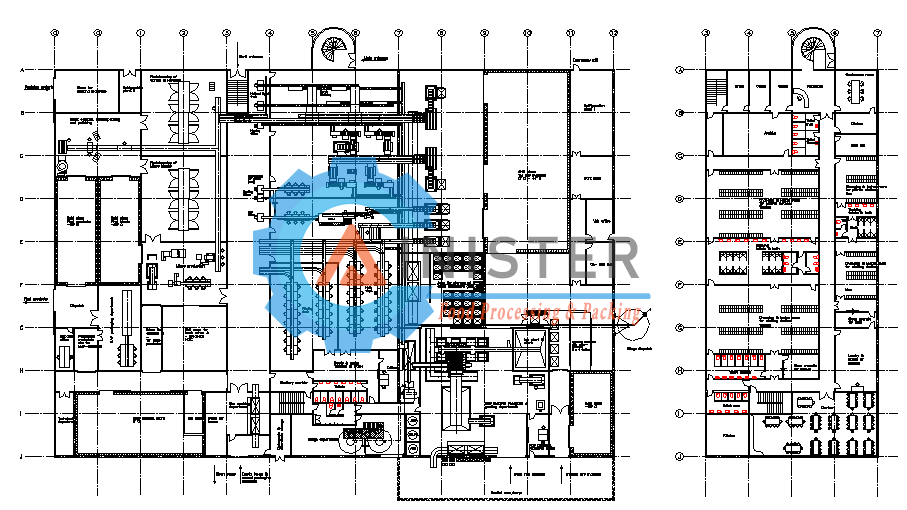

Layout Drawing & Specification

- 1.Compressed Air:0.06 Mpa

- 2.Steam Pressure:0.06-0.08 Mpa

- 3.Power: 3~380V/220V Or Customized according to different voltages.

- 4.Production Capacity:100kg-2000kg per hour.

- 5.Applicable Products: Luncheon meat, canned beef, canned pork, canned meat, etc.

- 6.Warranty Period: One year

- 7.Quality Certification: ISO9001, CE, UL

Product detail pictures:

Related Product Guide:

Quality comes first; service is foremost; business is cooperation" is our business philosophy which is constantly observed and pursued by our company for Hot Sale for Gyoza Wrapper Making Machine - Luncheon Meat Production Line – Ainister , The product will supply to all over the world, such as: Bhutan, Seychelles, Swansea, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad and create a great future together.

1.Do you provide goods or equipment, or solutions?

We do not produce final products, but are manufacturers of food processing equipment, and we also integrate and provide complete production lines for food processing plants.

2.What areas do your products and services involve?

As an integrator of the production line program of Helper Group, we not only provide various food processing equipment, such as: vacuum filling machine, chopping machine, automatic punching machine, automatic baking oven, vacuum mixer, vacuum tumbler, frozen meat/ Fresh meat grinder, noodle making machine, dumpling making machine, etc.

We also provide the following factory solutions, such as:

Sausage processing plants,noodle processing plants, dumpling plants, canned food processing plants, pet food processing plants, etc., involve a wide range of different food processing and production fields.

3.Which countries are your equipment exported to?

Our customers are all over the world, including the United States, Canada, Colombia, Germany, France, Turkey, South Korea, Singapore, Vietnam, Malaysia, Saudi Arabia, India, South Africa and more than 40 countries and regions, providing customized solutions for different customers.

4.How do you guarantee the installation and after-sales service of the equipment?

We have an experienced technical team and production workers, who can provide remote guidance, on-site installation and other services. The professional after-sales team can communicate remotely at the first time, and even on-site repairs.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.