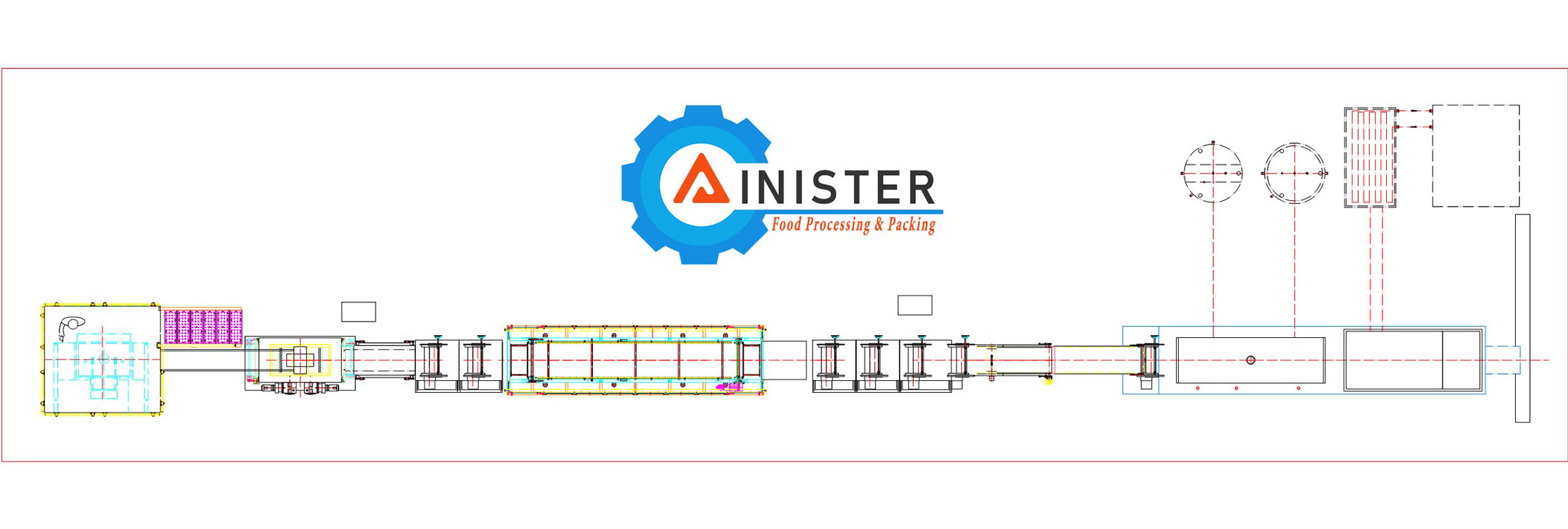

High Quality Noodles Production Process - Frozen cooked noodles production line – Ainister

High Quality Noodles Production Process - Frozen cooked noodles production line – Ainister Detail:

We have more than 20 years of experience in the production of pasta equipment. In China, we provide equipment to the largest noodle production companies. In other countries, we also provide technical support and customized services for different customers, which has earned us a good reputation.

The vacuum dough kneading machine is developed by our research group independently, as the most advanced dough kneader/mixer, it is suitable for all kinds of pasta products processing, you can achieve different dough kneading effects by the different types of stirring shafts up to the features of wheat powder.

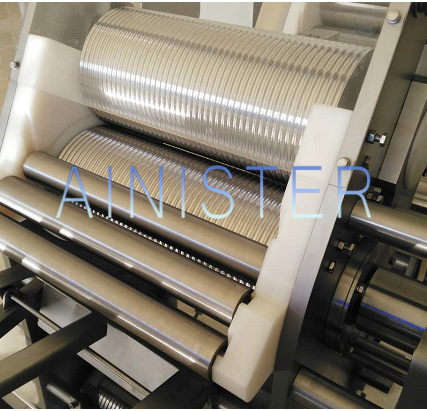

High-precision rolls made of special stainless steel are selected to ensure the long term rust resistance. Even the water percentage reaches 50%, with no risk of adhesion of dough. Thus to solve the problem of making noodles with more water. Imitates manual mixing, with low noise and stable operation.

At the dough aging step, we set aside the traditional vertical layers aging way, but to select the horizontal suspended type. The dough sheet moves forward slowly and continuously on the hanging sticks at a horizontal level.

The noodles are automatically divided into portions, boiled directly, the unit weight is adjustable, cooled with cold water, and transferred to manual picking or automatic packaging machine to complete the packaging. Realize automated production and reduce labor costs.

This production line will not only meet the requirements of noodle production but also enlarge your dough wrapper production without increasing working stuff. It adopts with roller cutter and knife cutter in actual production. which can customize different shapes of dough, round, square, triangle, etc., and adjust different thicknesses to meet manual production or other production requirements.

The noodles made by the vacuum dough mixer machine have good toughness and strong taste. They will not be rotten for a long time and easy to preserve. With different accessories, they can meet the needs of different tastes.

Product detail pictures:

Related Product Guide:

Our pursuit and enterprise goal is to "Always satisfy our customer requirements". We keep on to establish and style and design outstanding top quality goods for both our outdated and new prospects and realize a win-win prospect for our clientele likewise as us for High Quality Noodles Production Process - Frozen cooked noodles production line – Ainister , The product will supply to all over the world, such as: Belgium, Iraq, Comoros, We always stick to the tenet of "sincerity, high quality, high efficiency, innovation". With years of efforts, we have established friendly and stable business relationships with worldwide customers. We welcome any of your inquiries and concerns for our products, and we are sure that we will offer just what you want, as we always believe that your satisfaction is our success.

1.Do you provide goods or equipment, or solutions?

We do not produce final products, but are manufacturers of food processing equipment, and we also integrate and provide complete production lines for food processing plants.

2.What areas do your products and services involve?

As an integrator of the production line program of Helper Group, we not only provide various food processing equipment, such as: vacuum filling machine, chopping machine, automatic punching machine, automatic baking oven, vacuum mixer, vacuum tumbler, frozen meat/ Fresh meat grinder, noodle making machine, dumpling making machine, etc.

We also provide the following factory solutions, such as:

Sausage processing plants,noodle processing plants, dumpling plants, canned food processing plants, pet food processing plants, etc., involve a wide range of different food processing and production fields.

3.Which countries are your equipment exported to?

Our customers are all over the world, including the United States, Canada, Colombia, Germany, France, Turkey, South Korea, Singapore, Vietnam, Malaysia, Saudi Arabia, India, South Africa and more than 40 countries and regions, providing customized solutions for different customers.

4.How do you guarantee the installation and after-sales service of the equipment?

We have an experienced technical team and production workers, who can provide remote guidance, on-site installation and other services. The professional after-sales team can communicate remotely at the first time, and even on-site repairs.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!