Factory wholesale Vegetable Chopper Slicer Dicer - Udon Noodles Production Line – Ainister

Factory wholesale Vegetable Chopper Slicer Dicer - Udon Noodles Production Line – Ainister Detail:

Udon noodles originated in the Tang Dynasty of China and flourished in Japan. According to the regulations of the Ministry of Agriculture, Forestry and Fisheries of Japan, machine-made noodles with a cross section of more than 1.7 mm can be called udon noodles. The texture is elastic and there are many types according to the production location and poor craftsmanship. Together with Japanese soba noodles and green tea noodles, they are called the three major noodles in Japan.

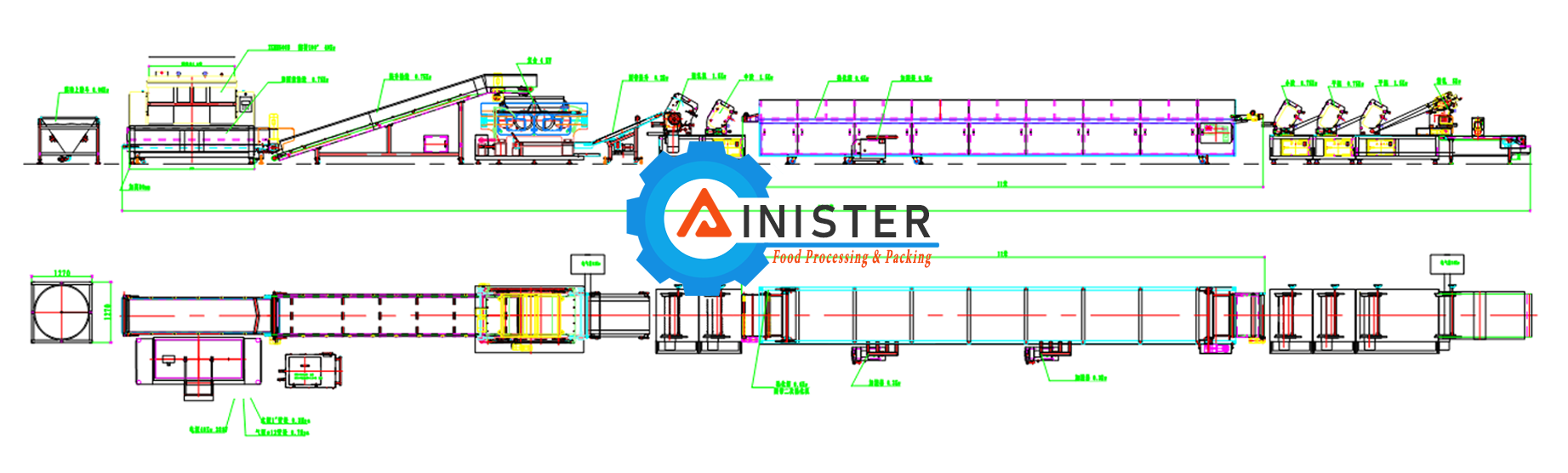

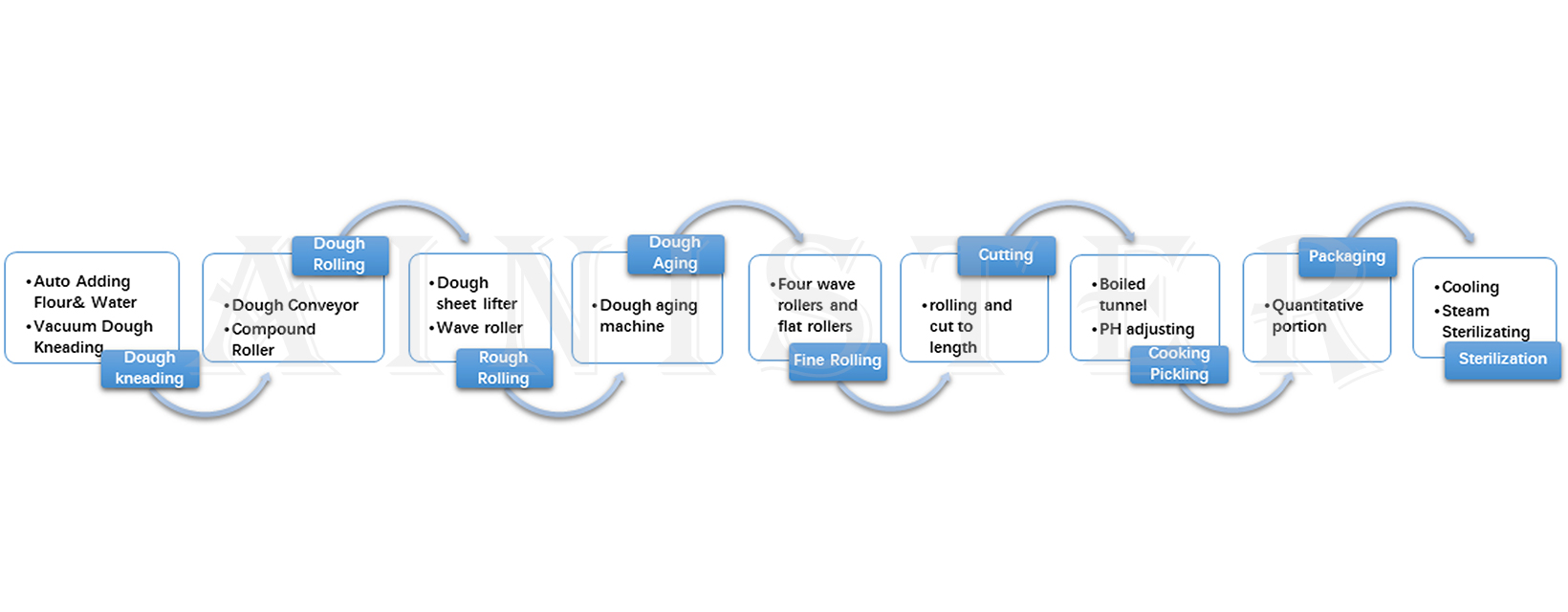

The production process of udon noodles is similar to the basic process of ordinary frozen cooked noodles. All need to go through the process of kneading, aging, rolling, cutting, and cooking. In the forming stage, the vacuum dough kneading machine and continuous rolling system are also needed to ensure that the dough sheet meets the appropriate moisture content and thickness requirements. A complete rolling system is a key to forming.

After the dough sheets are cut into strips with different specifications, the fresh noodles enter the continuous noodle cooker. Our noodle cooker has precise temperature control and adjustable formula parameters. It is suitable for noodle production of different processes. The unique noodle breaking device can effectively prevent the noodles from sticking and ensure the good shape of the final noodles.

The noodles in the cooking pot need to be cooled, and then adjusted by soaking in acid liquid to adjust the pH value in order to extend the shelf life.The steamed noodles need to be washed and cooled in cold water to prevent the noodles from being broken and clumped. In the processing of udon noodles, there is a unique processing technique, which is to adjust the pH value by soaking in acid solution to extend the shelf life. The washing and pickling equipment is made of 316 stainless steel, and the structure is broken up by air pressure, and all are automated.

The multi-station bag packaging machine used only in the packaging part can automatically complete the process of portioning, bag delivery, bag opening, vacuuming, sealing, etc., saving a series of drawbacks of manual packaging, visual touch screen operating system, real-time monitoring of packaging status, and at the same time The metal detection system can be matched to the production line to realize fully automated production.

Like most other cooked food products, the packaged udon noodles need to be sterilized to prevent the growth of microorganisms and to ensure that the shelf life of the udon noodles is 12 months. According to different output requirements and packaging forms, choose a suitable sterilization program. Including high-temperature steam sterilization, pasteurization, etc. The microcomputer controls the sterilization time and sterilization temperature to achieve the final treatment of the product.

Specification and Technical Parameter

- 1. Compressed Air:0.06 Mpa

- 2. Steam Pressure:0.06-0.08 Mpa

- 3. Power: 3~380V/220V Or Customized according to different voltages.

- 4. Production Capacity:200kg-2000kg per hour.

- 5. Applicable Products: Udon noodle, frozen udon noodle, fresh udon noodle, etc.

- 6. Warranty Period: One year

- 7. Quality Certification: ISO9001, CE, UL

Product detail pictures:

Related Product Guide:

We insist on the principle of development of 'High quality, Efficiency, Sincerity and Down-to-earth working approach' to provide you with excellent service of processing for Factory wholesale Vegetable Chopper Slicer Dicer - Udon Noodles Production Line – Ainister , The product will supply to all over the world, such as: Canada, Atlanta, Norway, Certainly, competitive price, suitable package and timely delivery will be assured as per customers' demands. We sincerely hope to build business relationship with you on the basis of mutual benefit and profit in the very near future. Warmly welcome to contact us and become our direct cooperators.

1.Do you provide goods or equipment, or solutions?

We do not produce final products, but are manufacturers of food processing equipment, and we also integrate and provide complete production lines for food processing plants.

2.What areas do your products and services involve?

As an integrator of the production line program of Helper Group, we not only provide various food processing equipment, such as: vacuum filling machine, chopping machine, automatic punching machine, automatic baking oven, vacuum mixer, vacuum tumbler, frozen meat/ Fresh meat grinder, noodle making machine, dumpling making machine, etc.

We also provide the following factory solutions, such as:

Sausage processing plants,noodle processing plants, dumpling plants, canned food processing plants, pet food processing plants, etc., involve a wide range of different food processing and production fields.

3.Which countries are your equipment exported to?

Our customers are all over the world, including the United States, Canada, Colombia, Germany, France, Turkey, South Korea, Singapore, Vietnam, Malaysia, Saudi Arabia, India, South Africa and more than 40 countries and regions, providing customized solutions for different customers.

4.How do you guarantee the installation and after-sales service of the equipment?

We have an experienced technical team and production workers, who can provide remote guidance, on-site installation and other services. The professional after-sales team can communicate remotely at the first time, and even on-site repairs.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.