Factory supplied Juicy Jelly Production Line - Shrimp Paste Production Line – Ainister

Factory supplied Juicy Jelly Production Line - Shrimp Paste Production Line – Ainister Detail:

How to make shrimp paste and fish paste with the automatic vacuum stuffer machine?

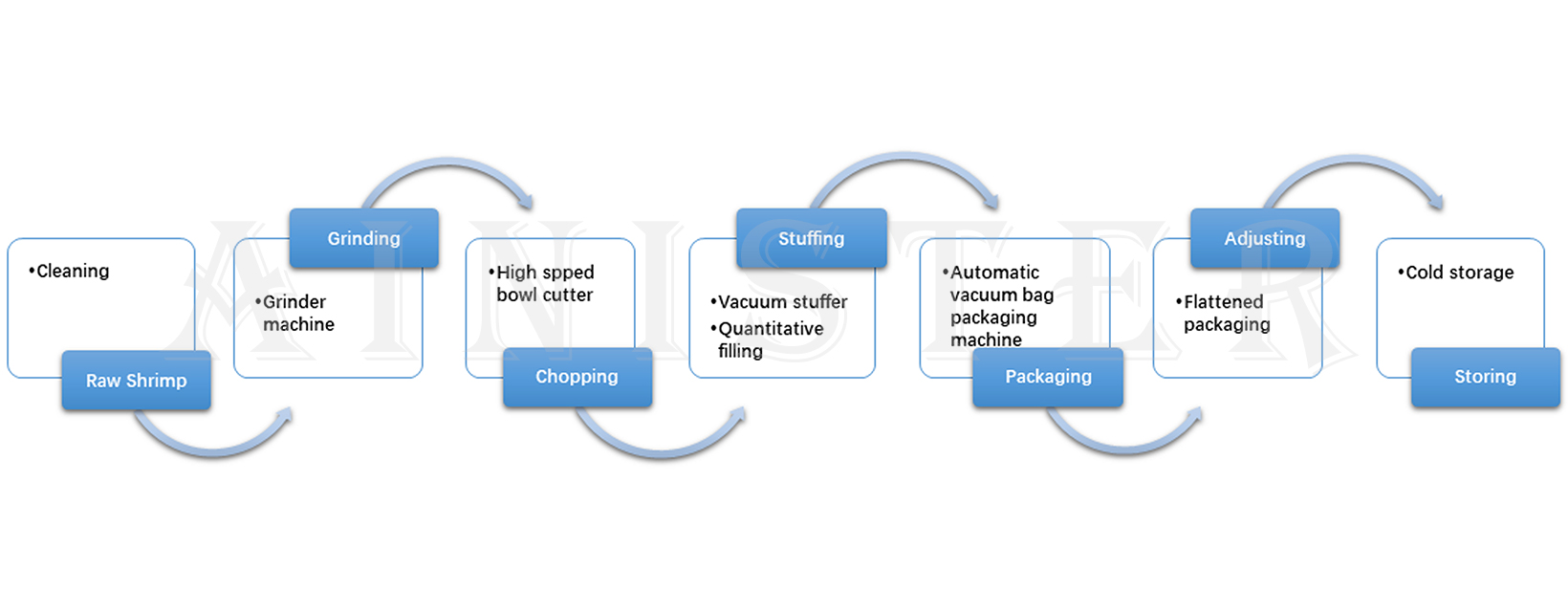

Shrimp paste is processed by processing the shrimp to make minced meat. After being cooked, it tastes firm and has a strong shrimp flavor. It is generally a popular dish for hot pot. The automated processing technology requires the shrimp to pass through the meat grinder, chopper, filling machine, packaging machine, quick-freezer, and other equipment, and refrigerate for standby. It is convenient and quick to cook it when eating.

Equipment Display

The processed and cleaned shrimp meat is passed through a meat grinder into granules. The meat grinder relies on the screw to push the raw meat in the hopper box to the pre-cutting plate. Through the rotation of the screw, the mincer and the orifice plate produce relative movement. In order to eliminate the defects of different types of raw meat, soft and hard, and fiber thickness, the uniformity of the meat filling is ensured. The main body of the meat grinder is made of stainless steel. The equipment has a reasonable structure, beautiful appearance, stable and reliable mechanical performance, clean and sanitary, and low noise. The raw materials do not need to be thawed, and the meat grinder can directly process frozen meat at around -18°C.

Shrimp pastes also have product differences. Depending on the taste, you can choose to add equipment such as a chopper or a beater. The shrimp meat after the meat grinder is chopped more delicately to make the taste more delicate without graininess. The speed of the chopper is fast, which adjusted by the frequency converter, and the temperature rise is small to ensure the freshness of the material.

For the filling of shrimp paste, a filling machine with vacuum function is used to facilitate the flow of materials. By connecting with the vacuum packaging machine, the automation of shrimp paste production can be realized, reducing labor and space occupation. In addition, with the servo control system, the quantification is accurate, which can not only fill ordinary meat emulsion with better fluidity, but also have good results for viscous materials. The vacuum filling machine has complete functions and can be combined with a variety of molding and packaging equipment to form a production line. It is suitable for different products such as shrimp pastes, sausages, ham, meatballs, canned food, dried meat, luncheon meat, etc.

Single-shaft transmission and inner cam design, fast packaging speed, more stable operation, easier maintenance, and reduce defective rate. Modular heating, more precise temperature control, and alarm for heating failure. The advanced design concept reduces the loss of packaging materials, ensures the stability of the equipment operation, and extends the operating life of the equipment. The machine has a wide range of packaging, which can pack all kinds of bagged materials for liquid, sauce, granules, powder, and solids. It only needs to use different metering devices according to different materials.

304 stainless steel whole welding process, high strength, no deformation, The insulation layer is no less than 150mm. Food grade stainless steel conveyor belt and chain transmission mechanism, high strength chain and chain wheel, polymer sliding bearing, not easy to wear, long life, Imported frequency control, freezing time adjustable. The tunnel adopts a Liquid nitrogen spray system, with PID automatic adjustment function, Independent low oxygen safety alarm system, when the oxygen concentration in the operation room drops to the set value, the sound, and the light alarm is started, and there is an alarm shock output, which can start the strong exhaust system in the user’s workshop.

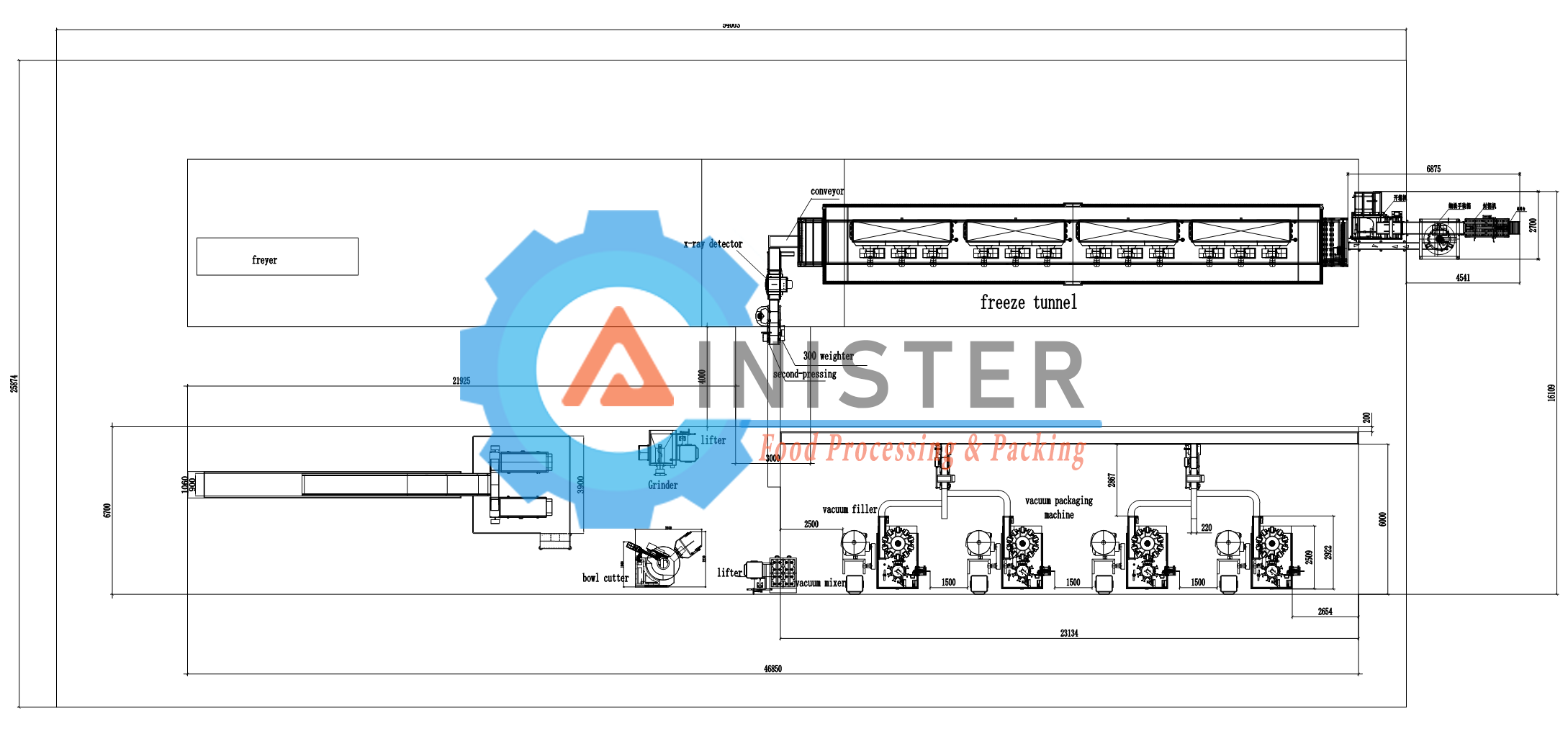

Layout Drawing & Specification

- 1. Compressed Air:0.06 Mpa

- 2. Steam Pressure:0.06-0.08 Mpa

- 3. Power:3~380V/220V Or Customized according to different voltages.

- 4. Production Capacity:200kg-2000kg per hour.

- 5. Applicable Products: shrimp paste.

- 6. Warranty Period: One year

- 7. Quality Certification: ISO9001, CE, UL

Product detail pictures:

Related Product Guide:

The pretty loaded projects management experiences and one to a person support model make the high importance of business enterprise communication and our easy understanding of your expectations for Factory supplied Juicy Jelly Production Line - Shrimp Paste Production Line – Ainister , The product will supply to all over the world, such as: Bangladesh, Austria, San Francisco, Our staffs are adhering to the "Integrity-based and Interactive Development" spirit, and the tenet of "First-class Quality with Excellent Service". According to the needs of every customer, we provide customized & personalized services to help customers achieve their goals successfully. Welcome clients from home and abroad to call and inquire!

1.Do you provide goods or equipment, or solutions?

We do not produce final products, but are manufacturers of food processing equipment, and we also integrate and provide complete production lines for food processing plants.

2.What areas do your products and services involve?

As an integrator of the production line program of Helper Group, we not only provide various food processing equipment, such as: vacuum filling machine, chopping machine, automatic punching machine, automatic baking oven, vacuum mixer, vacuum tumbler, frozen meat/ Fresh meat grinder, noodle making machine, dumpling making machine, etc.

We also provide the following factory solutions, such as:

Sausage processing plants,noodle processing plants, dumpling plants, canned food processing plants, pet food processing plants, etc., involve a wide range of different food processing and production fields.

3.Which countries are your equipment exported to?

Our customers are all over the world, including the United States, Canada, Colombia, Germany, France, Turkey, South Korea, Singapore, Vietnam, Malaysia, Saudi Arabia, India, South Africa and more than 40 countries and regions, providing customized solutions for different customers.

4.How do you guarantee the installation and after-sales service of the equipment?

We have an experienced technical team and production workers, who can provide remote guidance, on-site installation and other services. The professional after-sales team can communicate remotely at the first time, and even on-site repairs.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!