factory low price Citric Acid In Bacon Production - Mini Sausage Production Line – Ainister

factory low price Citric Acid In Bacon Production - Mini Sausage Production Line – Ainister Detail:

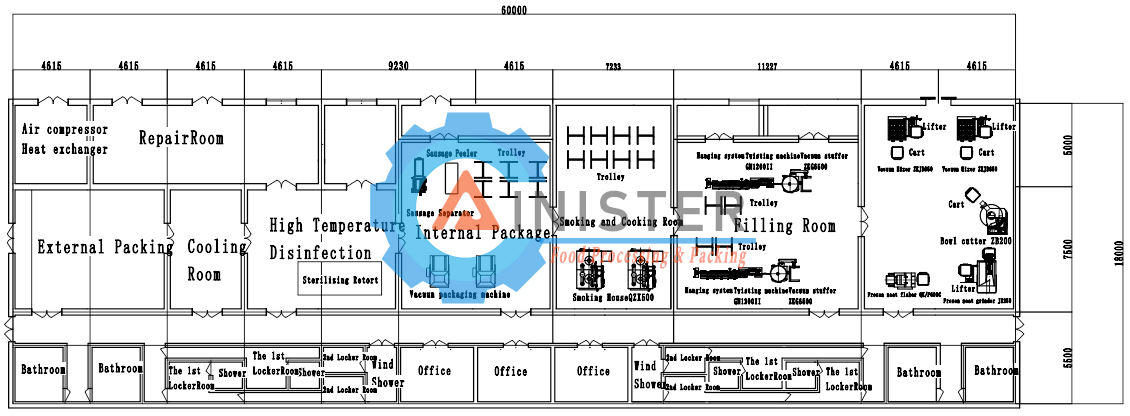

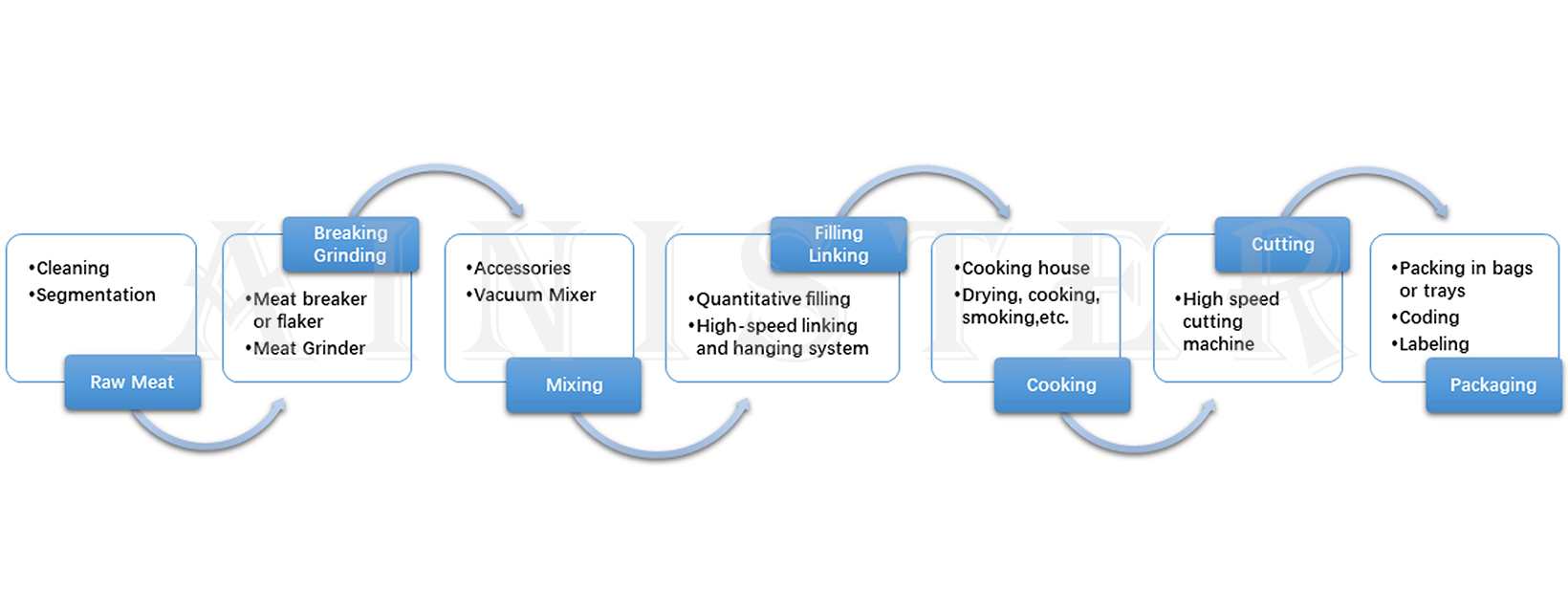

Mini sausages refer to small-sized sausages, generally within 5cm in length and about 10g in weight. They can be used as snack sausages, hot pot sausages, etc. The raw materials of mini sausages are generally the same as ordinary sausages, mainly chicken, pork, beef, etc. It also requires grinding, mixing, filling, cooking, etc. The finished product can be eaten directly, or fried, mixed with other ingredients to make different delicacies, etc. Various flavors, crispy and delicious.

The mini sausage production line needs to process the raw meat first. Whether it is fresh meat or frozen meat, it needs a meat grinder to crush it. It can be matched with different size orifice plates according to different process requirements to achieve different sausage tastes. In addition to processing divided frozen meat and fresh meat, it can also process whole chickens with bones.Meat grinder is the key equipment of meat processing equipment, which is widely used in sausage production line, dumpling production line, bacon production line, canned food production line, pet food production line, etc.

The chopper is another important equipment for the sausage production line, including ordinary chopper and vacuum chopper. The function of the chopper is to process the crushed meat material or the meat material initially processed by the meat grinder for a further step. It can achieve the emulsification effect and is suitable for the production of different meat products, not only suitable for meat product processing, but also for the crushing and cutting of soy protein and additives.

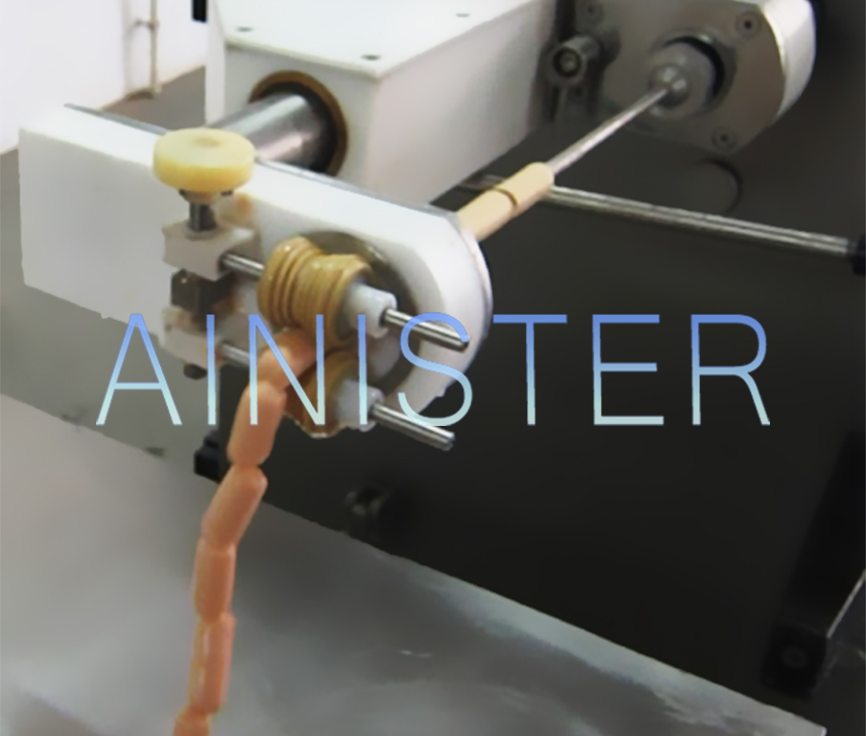

The production equipment for mini sausages is similar to ordinary sausage equipment, but due to size limitations, more precise quantification is required. So a good filling machine and twisting equipment are the core elements of making good sausages. Sausage filling machine equipped with kink function and vacuum function is the first choice. It has fast speed, accurate dosing, and high wear resistance of accessories. It can also be equipped with a lifting structure to assist feeding to achieve all-in-one function.Of course, for large-scale requirement, it can be equipped with a high-speed twisting machine and an automatic hanging system to complete automated production.

The last step of the sausage production line is cooking and smoking, and the process needs to be changed according to the taste of the sausage. The smoker is controlled by a computer, combined with high-precision temperature and humidity sensors, so that the temperature in the furnace can be automatically controlled. The filling of low thermal conductivity thermal insulation material makes less heat loss and better thermal insulation effect. It can realize the functions of cooking, drying, smoking, humidity control and exhaust. In addition to sausage processing, it is also suitable for the processing of bacon, jerky and other products.

Specification and Technical Parameter

1. Compressed Air:0.06 Mpa

2. Steam Pressure:0.06-0.08 Mpa

3. Power:3~380V/220V Or Customized according to different voltages.

4. Production Capacity:200kg-5000kg per hour.

5. Applicable Products: Small sausages, twisted sausages, salami, smoked sausage, etc.

6. Warranty Period: One year

7. Quality Certification: ISO9001, CE, UL

Product detail pictures:

Related Product Guide:

Our firm since its inception, normally regards item top quality as company life, constantly make improvements to generation technology, improve product excellent and repeatedly strengthen organization total good quality management, in strict accordance with the national standard ISO 9001:2000 for factory low price Citric Acid In Bacon Production - Mini Sausage Production Line – Ainister , The product will supply to all over the world, such as: Riyadh, Macedonia, Accra, Our products are mainly exported to Europe, Africa, America, the Middle East and Southeast Asia and other countries and regions. We have enjoyed a great reputation among our customers for quality products and good services.We would make friends with businessmen from at home and abroad, following the purpose of "Quality First, Reputation First, the Best Services."

1.Do you provide goods or equipment, or solutions?

We do not produce final products, but are manufacturers of food processing equipment, and we also integrate and provide complete production lines for food processing plants.

2.What areas do your products and services involve?

As an integrator of the production line program of Helper Group, we not only provide various food processing equipment, such as: vacuum filling machine, chopping machine, automatic punching machine, automatic baking oven, vacuum mixer, vacuum tumbler, frozen meat/ Fresh meat grinder, noodle making machine, dumpling making machine, etc.

We also provide the following factory solutions, such as:

Sausage processing plants,noodle processing plants, dumpling plants, canned food processing plants, pet food processing plants, etc., involve a wide range of different food processing and production fields.

3.Which countries are your equipment exported to?

Our customers are all over the world, including the United States, Canada, Colombia, Germany, France, Turkey, South Korea, Singapore, Vietnam, Malaysia, Saudi Arabia, India, South Africa and more than 40 countries and regions, providing customized solutions for different customers.

4.How do you guarantee the installation and after-sales service of the equipment?

We have an experienced technical team and production workers, who can provide remote guidance, on-site installation and other services. The professional after-sales team can communicate remotely at the first time, and even on-site repairs.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.