factory customized Collagen Casing Jelly Production Line - Boiled Dumpling Production Line – Ainister

factory customized Collagen Casing Jelly Production Line - Boiled Dumpling Production Line – Ainister Detail:

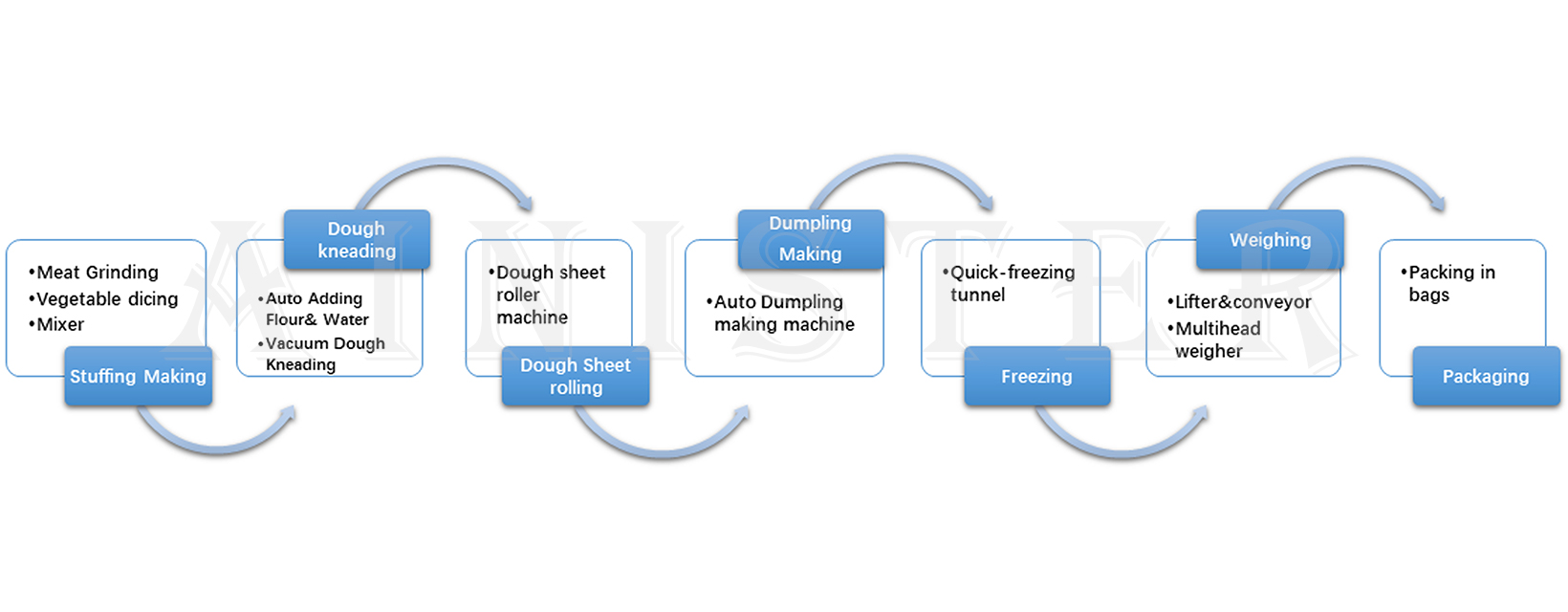

Dumplings, whether in Asia, America, or Europe, have a large number of fans, they are loved by foodies all over the world. The filling is rich and the taste is delicious. With the help of modern automatic production, we can save ourselves from the tedious production process. Just cook and enjoy it immediately. We can provide a complete dumpling production line.

For different customer groups, we provide different production solutions, which are fully applicable to the different output requirements of different types of customers such as catering distribution, food factories, and large supermarkets.It can also be used as an assistant for small factories that start with household production.

In order to meet the safety and sanitation requirements of the modern food industry, the main components are made of food-specific stainless steel materials, and the conveying surface and forming parts are made of special anti-adhesive technology materials, with low resistance, good molding, wear resistance and pressure resistance, disassembly, assembly, and cleaning Convenient and durable.

For the preparation of dumpling fillings, including the processing of meat and vegetables, after the meat is divided, it is chopped into pellets via dicing machines, meat grinders and other equipment. The production lines all use equipment assembled in our own factory. The size of the meat filling can be adjusted, and the output range is wide to meet the needs of different customers.The equipment is made of food-grade high-quality stainless steel, with high knife strength, wear resistance and easy cleaning.

There are many kinds of dumplings. In addition to the shapes, the fillings are also rich and varied. In our production line, the dumpling forming equipment can produce dumplings of different shapes by changing the molds, such as curry dumplings, guotie(potstickers),etc., and can fill different fillings, meat, vegetable fillings, and mixes. Stuffing, etc., one machine has multiple uses, which greatly reduces costs and improves product productivity and competitiveness.

After the dumplings are formed, they are usually frozen by quick-freezing equipment, so that the dumplings are easy to pack, reduce damage and extend the shelf life. For low labor costs and little difference in output, manual weighing solutions can be used. For areas with high output requirements and high labor costs, you can choose to adapt to automatic packaging machines.

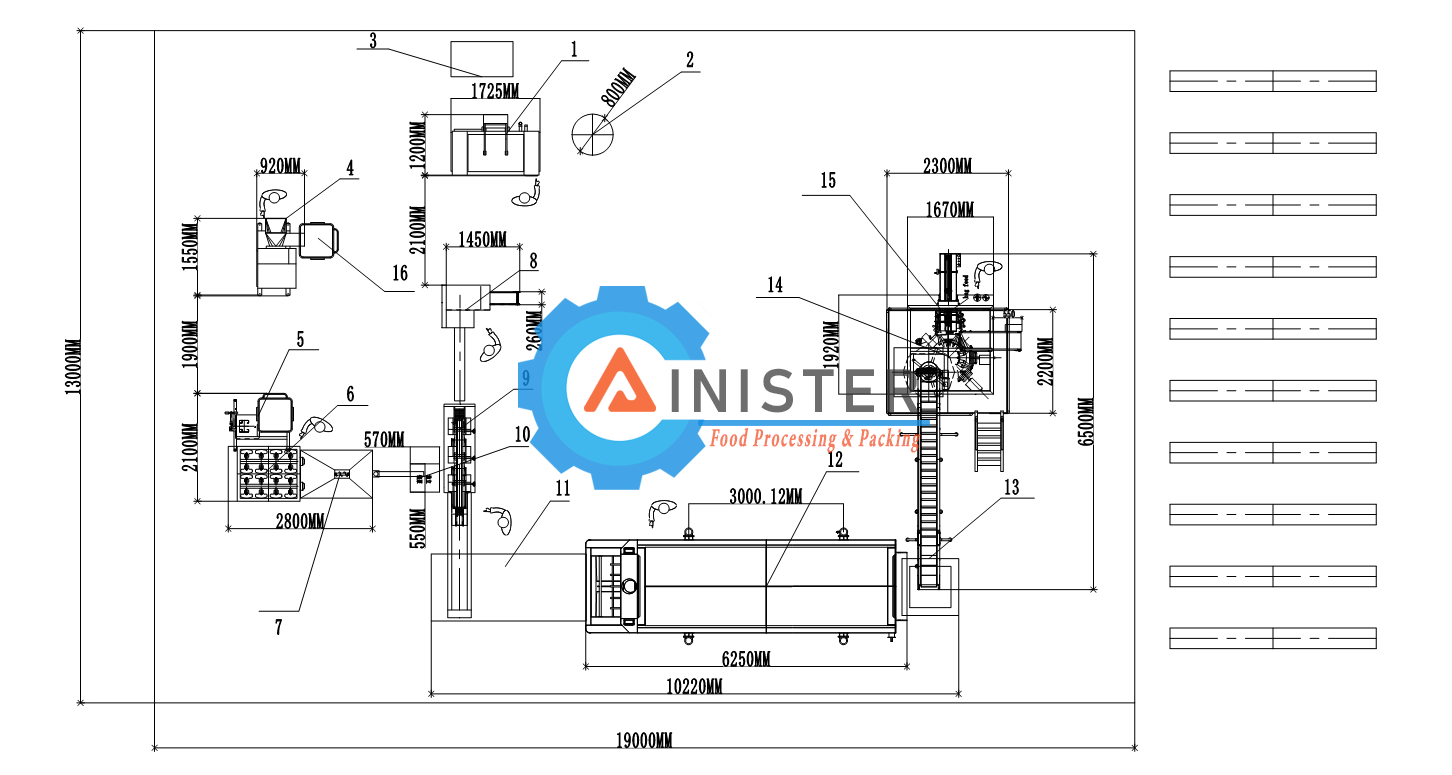

Specification and Technical Parameter

- 1. Compressed Air:0.06 Mpa

- 2. Steam Pressure:0.06-0.08 Mpa

- 3. Power: 3~380V/220V Or Customized according to different voltages.

- 4. Production Capacity:200kg-2000kg per hour.

- 5. Applicable Products: Boiled dumplings, frozen dumplings, Jiaozi, etc.

- 6. Warranty Period: One year

- 7. Quality Certification: ISO9001, CE, UL

Product detail pictures:

Related Product Guide:

Always customer-oriented, and it's our ultimate target to be not only the most reliable, trustable and honest supplier, but also the partner for our customers for factory customized Collagen Casing Jelly Production Line - Boiled Dumpling Production Line – Ainister , The product will supply to all over the world, such as: Muscat, Philippines, Marseille, You can do one-stop shopping here. And customized orders are acceptable. Real business is to get win-win situation, if possible, we would like to provide more support for customers. Welcome all nice buyers communicate details of products and ideas with us!!

1.Do you provide goods or equipment, or solutions?

We do not produce final products, but are manufacturers of food processing equipment, and we also integrate and provide complete production lines for food processing plants.

2.What areas do your products and services involve?

As an integrator of the production line program of Helper Group, we not only provide various food processing equipment, such as: vacuum filling machine, chopping machine, automatic punching machine, automatic baking oven, vacuum mixer, vacuum tumbler, frozen meat/ Fresh meat grinder, noodle making machine, dumpling making machine, etc.

We also provide the following factory solutions, such as:

Sausage processing plants,noodle processing plants, dumpling plants, canned food processing plants, pet food processing plants, etc., involve a wide range of different food processing and production fields.

3.Which countries are your equipment exported to?

Our customers are all over the world, including the United States, Canada, Colombia, Germany, France, Turkey, South Korea, Singapore, Vietnam, Malaysia, Saudi Arabia, India, South Africa and more than 40 countries and regions, providing customized solutions for different customers.

4.How do you guarantee the installation and after-sales service of the equipment?

We have an experienced technical team and production workers, who can provide remote guidance, on-site installation and other services. The professional after-sales team can communicate remotely at the first time, and even on-site repairs.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.