Factory best selling Casing Juicy Jelly Production Solution - Stuffed Bun/Baozi Production Line – Ainister

Factory best selling Casing Juicy Jelly Production Solution - Stuffed Bun/Baozi Production Line – Ainister Detail:

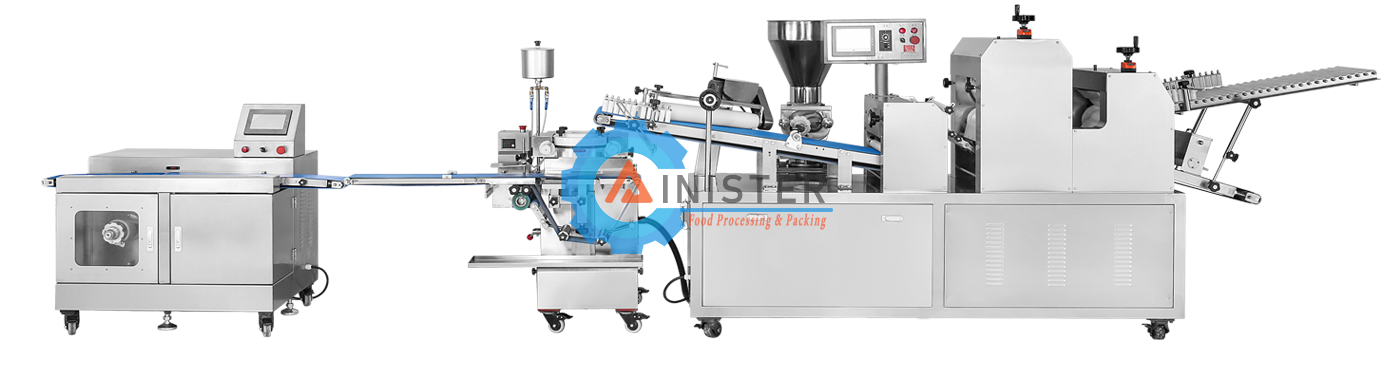

The automatic imitation hand-made bun production line imitates hand-made, rolls the dough into strips, does not damage the tissue composition of the dough, imitates the hand-kneaded flower, the flower shape is natural, beautiful, and generous, the product has high gluten and good taste. It is controlled by a step-less speed regulation system, and the product weight and length are adjustable. The whole machine is made of stainless steel and is controlled by a touch screen computer.

Improved slow-pressure dough conveying system, with larger dough conveying volume, and the weight of a single bun can be selected from 20-150g. The improved vortex filling system makes the filling more smooth and even, and solves the problems of uneven meat and vegetable filling in the past bun machine.

Imported double frequency conversion control, the size of dough and fillings can be adjusted freely, and the accuracy is high in use. Lightweight body, reasonable design, compact structure, easy to move, and does not take up space.It is made of high-quality stainless steel, durable, beautiful and in line with national food hygiene standards.The products are of uniform size, smooth surface and neat patterns. Far more beautiful than a handmade one.

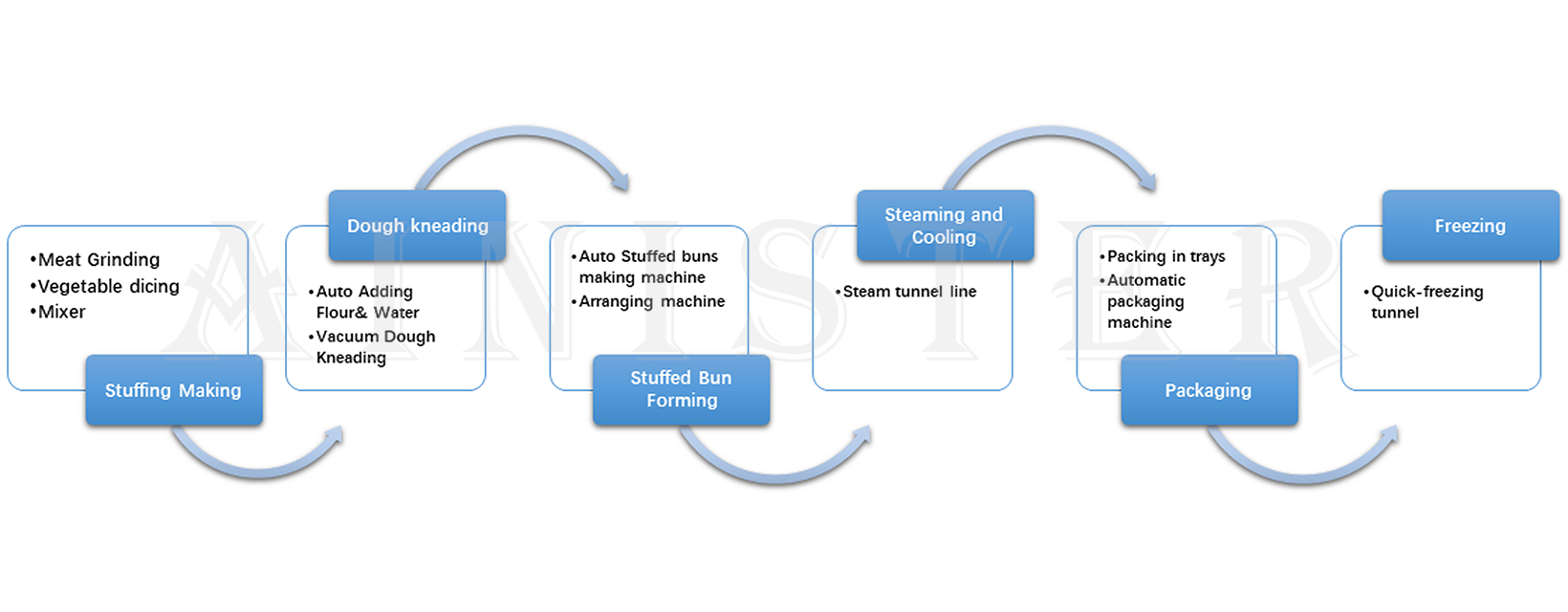

This production line can meet different requirements on different kinds of buns, it has a wide range of applications and can produce dozens of stuffing products such as various vegetable buns, tofu buns, sweet potato buns, bean paste buns, bean buns, meat buns, etc.The output can meet the needs of factories with a small scale of several hundred kilograms to a large output of several tons.

Specification and Technical Parameter

Compressed Air:0.06 Mpa

Steam Pressure:0.06-0.08 Mpa

Power: 3~380V/220V Or Customized according to different voltages.

Production Capacity:200kg-3000kg per hour.

Applicable Products: Frozen stuffed buns, Chashao Bao, Baozi, Meat buns, Xiaolongbao, etc.

Warranty Period: One year

Quality Certification: ISO9001, CE, UL

Product detail pictures:

Related Product Guide:

Our company sticks into the basic principle of "Quality is definitely the life of the business, and status may be the soul of it" for Factory best selling Casing Juicy Jelly Production Solution - Stuffed Bun/Baozi Production Line – Ainister , The product will supply to all over the world, such as: Senegal, Kazakhstan, Guatemala, We believe with our consistently excellent service you can get the best performance and cost least products from us for a long term . We commit to provide better services and create more value to all our customers. Hope we can create a better future together.

1.Do you provide goods or equipment, or solutions?

We do not produce final products, but are manufacturers of food processing equipment, and we also integrate and provide complete production lines for food processing plants.

2.What areas do your products and services involve?

As an integrator of the production line program of Helper Group, we not only provide various food processing equipment, such as: vacuum filling machine, chopping machine, automatic punching machine, automatic baking oven, vacuum mixer, vacuum tumbler, frozen meat/ Fresh meat grinder, noodle making machine, dumpling making machine, etc.

We also provide the following factory solutions, such as:

Sausage processing plants,noodle processing plants, dumpling plants, canned food processing plants, pet food processing plants, etc., involve a wide range of different food processing and production fields.

3.Which countries are your equipment exported to?

Our customers are all over the world, including the United States, Canada, Colombia, Germany, France, Turkey, South Korea, Singapore, Vietnam, Malaysia, Saudi Arabia, India, South Africa and more than 40 countries and regions, providing customized solutions for different customers.

4.How do you guarantee the installation and after-sales service of the equipment?

We have an experienced technical team and production workers, who can provide remote guidance, on-site installation and other services. The professional after-sales team can communicate remotely at the first time, and even on-site repairs.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.