2018 China New Design Sausage Stuffer - Twisting Sausage production line – Ainister

2018 China New Design Sausage Stuffer - Twisting Sausage production line – Ainister Detail:

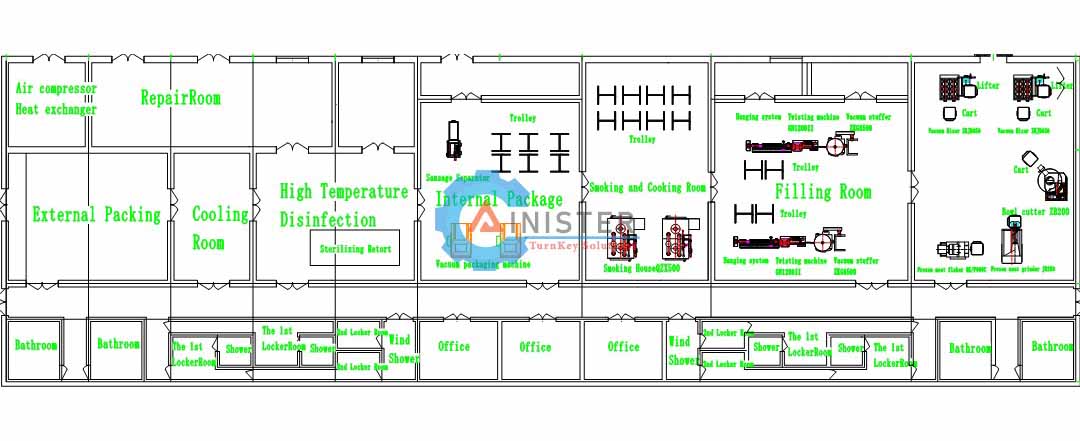

The sausage production line as our main product, after continuous improvement and innovation, can be applied to different product needs. From small-scale semi-automatic processing equipment to fully automatic processing production lines.It is also suitable for the production and processing of different raw materials, chicken, beef, and other sausages.We can provide a complete set of production solutions, from raw material processing to steaming and smoking, to final packaging.

In sausage production, frozen meat is generally selected as the raw material, so it needs to be broken by a flaker machine and then ground into meat by a meat grinder.The grinder is made of food-grade SUS304 high-quality stainless steel. The meat grinder directly grinds frozen meat at minus 18 degrees, also can be used in fresh meat with the different screw feeding parts. The temperature of the meat changes very little, and the size of the meat particles can be changed.

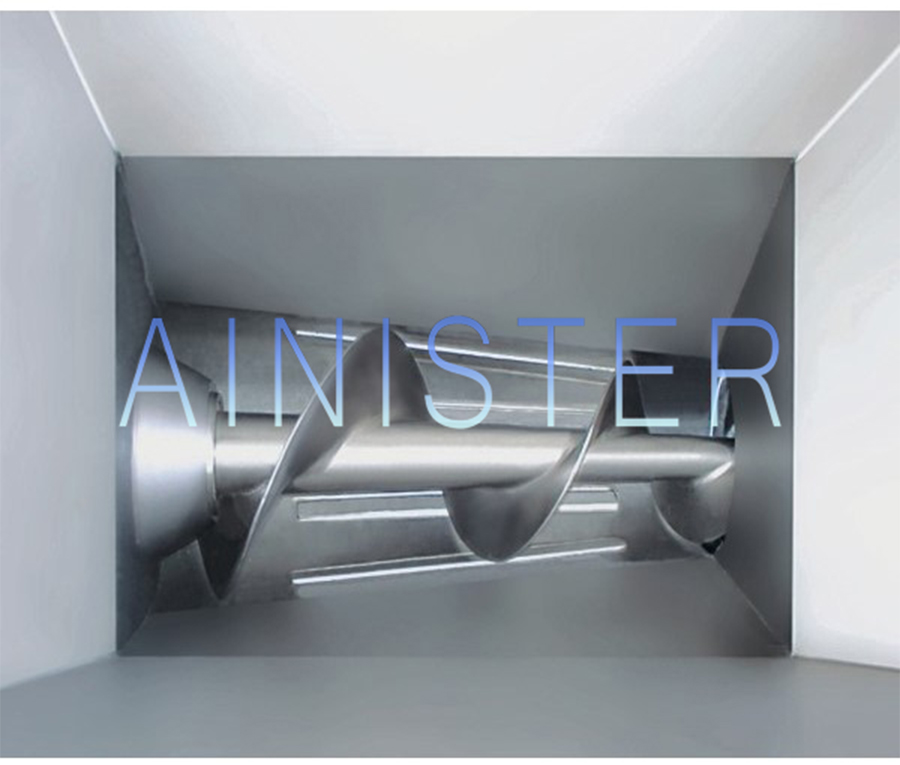

Meat processing is generally inseparable from the chopper. The blades of the high-speed chopper are sharp and durable, and the speed is adjusted by a frequency converter, which ensures stable high-speed operation. Good shredding and emulsification effect. Imported bearings, European standard motors, longer service life. For high-end products that require relatively high taste and shape, you can choose a vacuum system. Under -0.08mpa vacuum, the cutting and emulsification effect is better.

As the core equipment of the sausage production line, the vacuum filling machine determines the output and quality of the final product. After continuous accumulation of experience and customer feedback, the vacuum filling machine series have played a stable role in different customer groups.The vacuum filling machine adopts a servo control system, with PLC and HMI, there are mechanical filling, pneumatic filling, vacuum filling, and many other types. the operation is simple and intuitive. Can be used in conjunction with different equipment, such as a clipper machine, sausage linker machine,using different casings to increase product diversity.

It can be matched with different twisting structures, from the simplest integrated twisting system to a split-type high-speed twisting machine. At the same time, it can be matched with a sausage hanging system to meet customers with different output and different cost requirements.

Suitable for a variety of casings, natural casing, collagen casing, etc, the weight and size can be set according to needs. The product breakage rate is low and the appearance is good. At the same time, we also accept different types of casing orders. Comply with CE standards and other food-grade certifications. Realize the comprehensive coverage of food processing.

Another important part of the sausage production line-cooking, baking, or smoking. What is needed at this time is fully automatic smoker equipment. From 250kg/hour to dozens of tons/day, there are different plans. Using intelligent temperature control, high-definition touch screen, it can store up to 99 sets of formulas to meet the needs of different products. Optional equipment includes a smoke generator, steam generator, and other supporting equipment. Diversify products and avoid waste and duplication of equipment.

In view of the increasing requirements of customers for automation and the wider scope, we have been constantly transforming and innovating. The sausage separator is the result of our continuous research and development. It adopts dual-axis servo control, high speed and stability, suitable for different sausage sizes, and ends the traditional manual cutting. The speed can reach 65m/min, which greatly improves productivity and reduces labor costs.

Product detail pictures:

Related Product Guide:

Our firm promises all consumers with the first-class products as well as most satisfying post-sale services. We warmly welcome our regular and new consumers to join us for 2018 China New Design Sausage Stuffer - Twisting Sausage production line – Ainister , The product will supply to all over the world, such as: Bulgaria, Cairo, Mecca, With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

1.Do you provide goods or equipment, or solutions?

We do not produce final products, but are manufacturers of food processing equipment, and we also integrate and provide complete production lines for food processing plants.

2.What areas do your products and services involve?

As an integrator of the production line program of Helper Group, we not only provide various food processing equipment, such as: vacuum filling machine, chopping machine, automatic punching machine, automatic baking oven, vacuum mixer, vacuum tumbler, frozen meat/ Fresh meat grinder, noodle making machine, dumpling making machine, etc.

We also provide the following factory solutions, such as:

Sausage processing plants,noodle processing plants, dumpling plants, canned food processing plants, pet food processing plants, etc., involve a wide range of different food processing and production fields.

3.Which countries are your equipment exported to?

Our customers are all over the world, including the United States, Canada, Colombia, Germany, France, Turkey, South Korea, Singapore, Vietnam, Malaysia, Saudi Arabia, India, South Africa and more than 40 countries and regions, providing customized solutions for different customers.

4.How do you guarantee the installation and after-sales service of the equipment?

We have an experienced technical team and production workers, who can provide remote guidance, on-site installation and other services. The professional after-sales team can communicate remotely at the first time, and even on-site repairs.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.