2018 China New Design Sausage Stuffer - Steam Dumpling Production Line – Ainister

2018 China New Design Sausage Stuffer - Steam Dumpling Production Line – Ainister Detail:

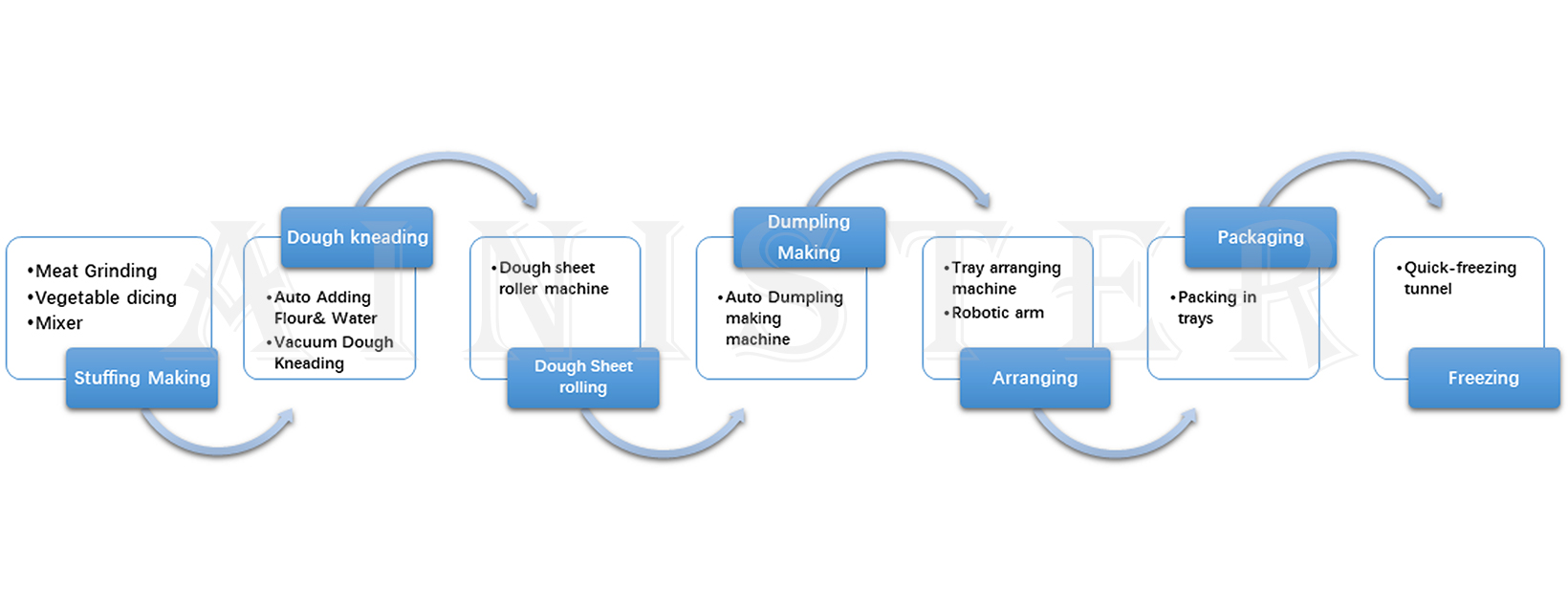

How to make steaming dumplings, fried dumpling with automatic dumpling forming maker machine?

Steamed dumplings are a common type of dumplings, the main difference lies in the shape and cooking method. The structure of dumplings is similar to that of hand-made, and they are actually stuffed rather than squeezed. Therefore, the appearance is better and it is convenient to place the plate. In addition, steamed dumplings are not only used for steaming, but also for frying, providing a different delicious experience. How to use an automated dumpling maker machine to make dumplings?

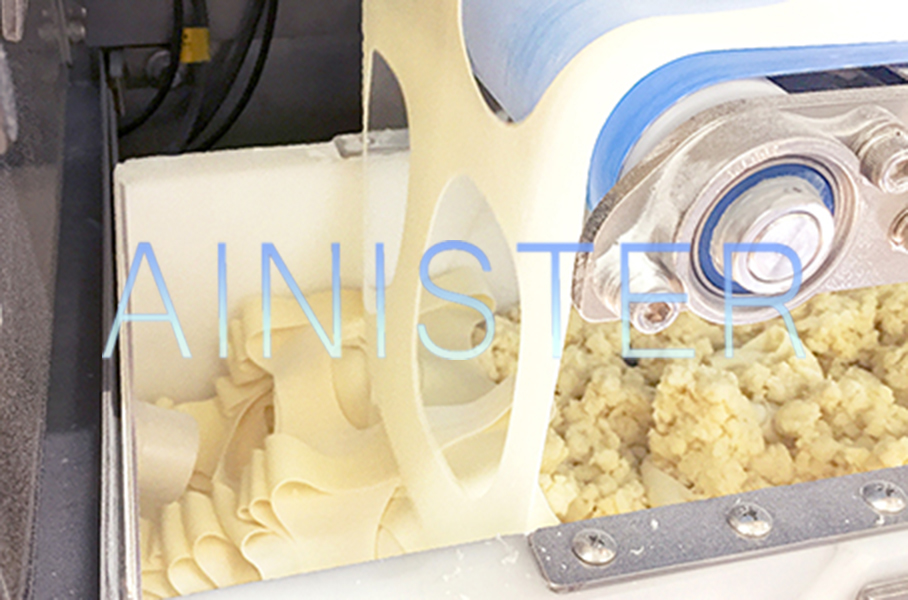

Equipment Display

Like ordinary dumplings, the production of dumpling wrapper and dumpling filling is similar, the main difference lies in the forming part.What is the core part of the dumpling production line? Of course it is a dumpling maker machine.Our dumpling machine adopts servo control, with PLC and touch screen, it is convenient to manage different products. The stainless steel body makes the equipment easy to clean and prolongs its service life.

The dumpling maker machine can also be equipped with a dough pressing system to reduce the production process and save time without taking up too much space. With the equipment’s own scrap recovery device, it greatly reduces the waste of raw materials and reduces labor costs.

There are servo motors to control all parts of the dumpling machine and there is no chain to drive the machine, which increases the capacity and stability of the dumpling machine and also makes operation and maintenance of the machine much easier, and also prolong the service life of the machine. The weight of filling can be adjusted on the touch screen and there is no need to adjust the filling part in the machine by hand. Moreover, due to the dual-channel structure, the speed can reach 160pcs/min.

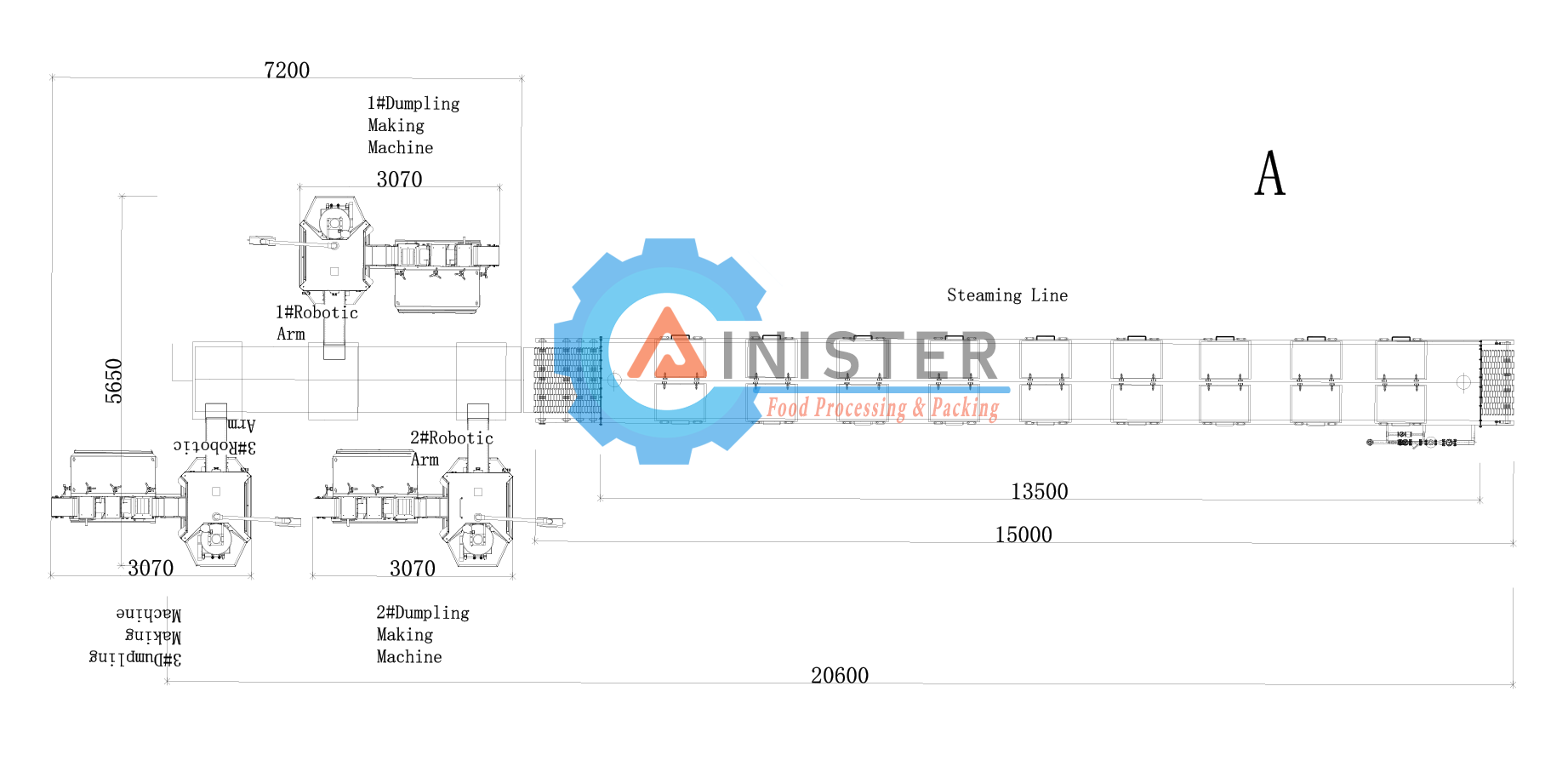

The automatic steaming dumpling production line can also be equipped with the dumpling arranging machine.Molded dumplings are pushed or put onto the transmission belt and then delivered to the catching component of the tray arranging machine, and then the robot arm catch dumplings and puts them into the tray. After the tray is filled with dumplings, the transmission chain delivers the tray out of the catching part.

The gripper of the dumpling catching component can be exchanged according to different dumpling shapes to meet the tray-loading requirements of different dumplings. The machine adopts frequency conversion and servo motor control which makes speed control convenient. All the operations and parameters can be conducted on the touch screen, with a high degree of automation, accurate positioning. And High-quality electrical components are adopted by the machine, which makes the control accurate and reliable. And The machine can be combined with several dumpling machines to meet the requirements of tidying up different kinds of dumplings.

For the automatic steaming line, it is a continuous tunnel design, the heating medium is steam, high-pressure steam (0.7-0.8mpa), after being decompressed into a stable low-pressure steam through the decompression system, it will directly enter the steaming line for product heating. The heat preservation shell is composed of stainless steel structure and heat preservation layer to ensure that the temperature in the automatic line will not be lost quickly. It can be operated automatically with PLC and touch screen.

For the packaging machine, using original single-servo or dual-servo motor control, which is more intelligent, higher packaging accuracy, wider adjustable range, more precise control, and lower scrap rate compared with other similar domestic and foreign inverter motor or inverter control products, Better stability. Due to the use of a fully open box structure, the transmission structure is clear, and maintenance is more convenient. It is applied for the packing of quick-frozen food such as dumplings, wontons, buns, and tangyuan with trays, or all kinds of solid and regular objects such as bread, cakes, cartoons, etc.

Layout Drawing & Specification

- 1. Compressed Air:0.06 Mpa

- 2. Steam Pressure:0.06-0.08 Mpa

- 3. Power: 3~380V/220V Or Customized according to different voltages.

- 4. Production Capacity:100kg-2000kg per hour.

- 5. Applicable Products: Steam dumplings, steam gyoza, instant pot dumplings, fried dumplings, etc.

- 6. Warranty Period: One year

- 7. Quality Certification: ISO9001, CE, UL

Product detail pictures:

Related Product Guide:

High quality Very first,and Consumer Supreme is our guideline to offer the most beneficial service to our consumers.At present, we're attempting our greatest to be among the top exporters in our area to fulfill buyers far more need to have for 2018 China New Design Sausage Stuffer - Steam Dumpling Production Line – Ainister , The product will supply to all over the world, such as: Armenia, Slovakia, Boston, Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our products and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

1.Do you provide goods or equipment, or solutions?

We do not produce final products, but are manufacturers of food processing equipment, and we also integrate and provide complete production lines for food processing plants.

2.What areas do your products and services involve?

As an integrator of the production line program of Helper Group, we not only provide various food processing equipment, such as: vacuum filling machine, chopping machine, automatic punching machine, automatic baking oven, vacuum mixer, vacuum tumbler, frozen meat/ Fresh meat grinder, noodle making machine, dumpling making machine, etc.

We also provide the following factory solutions, such as:

Sausage processing plants,noodle processing plants, dumpling plants, canned food processing plants, pet food processing plants, etc., involve a wide range of different food processing and production fields.

3.Which countries are your equipment exported to?

Our customers are all over the world, including the United States, Canada, Colombia, Germany, France, Turkey, South Korea, Singapore, Vietnam, Malaysia, Saudi Arabia, India, South Africa and more than 40 countries and regions, providing customized solutions for different customers.

4.How do you guarantee the installation and after-sales service of the equipment?

We have an experienced technical team and production workers, who can provide remote guidance, on-site installation and other services. The professional after-sales team can communicate remotely at the first time, and even on-site repairs.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.